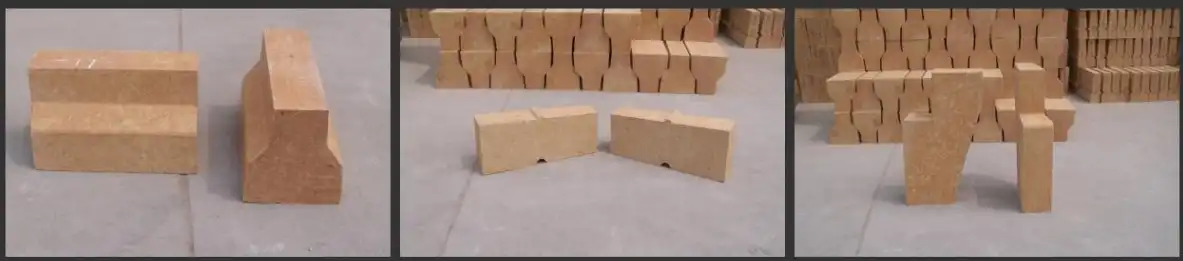

DRL-140 Low Creep Brick

Raw Materials:bauxite clinker,special additives

Advantage: High fire resistance,good corrosion resistance,customized production available

Application: It is mainly used in blast furnace, hot blast stove, baking furnace, carbon calciner, coking furnace, teeming ladle, casting system, boiler, cement kiln, glass furnace and all kinds of kiln linings and thermal equipment.

DRL-140 Low Creep Brick Manufacturer & Supplier

At TianYu Refractory Materials Co., LTD, we specialize in manufacturing and supplying DRL-140 Low Creep Brick—a superior refractory solution trusted by global steel manufacturers. With over 20 years of industry expertise, we guarantee unmatched quality, performance, and durability, ensuring your operations run smoothly with minimal downtime.

Why Choose DRL-140 Low Creep Brick?

Engineered for extreme industrial environments, DRL-140 Low Creep Brick provides exceptional resistance to high temperatures, pressure, and chemical corrosion. This results in longer service life, reduced maintenance, and cost savings for your steel production.

Key Advantages:

✔ Ultra-Low Creep Rate (<0.2% at 1400°C) – Ensures structural integrity under prolonged heat exposure.

✔ High-Temperature Resistance (Up to 1700°C) – Withstands extreme furnace conditions.

✔ Superior Cold Crushing Strength (>65 MPa) – Enhances durability and mechanical stability.

✔ Precision Machining – Guarantees seamless fitting and easy installation.

✔ Exceptional Chemical Stability – Resists slag, molten metal, and thermal shock.

✔ Customizable Dimensions – Tailored to fit your specific industrial needs.

OUR CERTIFICATE

Technical Specifications

| Attribute | Details |

|---|---|

| Material Composition | High alumina with advanced additives |

| Creep Resistance | <0.2% at 1400°C |

| Temperature Resistance | Up to 1700°C |

| Bulk Density | 2.3 g/cm³ |

| Cold Crushing Strength | >65 MPa |

| Dimensional Accuracy | Precision-machined for seamless fitting |

| Chemical Stability | Resistant to slag and molten metal erosion |

Industries & Applications

Our DRL-140 Low Creep Brick is widely used in high-temperature industrial applications, including:

Blast Furnaces – Ideal for lining hearths and walls, ensuring long-lasting durability.

Hot-Blast Stoves – Provides stable thermal performance under continuous heating cycles.

Torpedo Cars & Iron Ladles – Withstands extreme wear during molten metal transport.

Steel Mills – Designed for high-stress areas that demand superior heat and pressure resistance.

Advanced Manufacturing Process

At TianYu Refractory Materials, we implement a rigorous manufacturing process to guarantee outstanding quality and performance:

Raw Material Selection – High-purity materials undergo strict quality control.

Precision Formulation – Advanced additives enhance durability and thermal resistance.

High-Temperature Firing (>1500°C) – Strengthens structural integrity and longevity.

Strict Quality Testing – ISO-certified tests for creep resistance, strength, and accuracy.

Why Partner with TianYu Refractory?

✔ 20+ Years of Expertise – Trusted by leading global steel manufacturers.

✔ Innovative R&D – 21 patents in refractory materials and continuous product improvement.

✔ Customization Available – Tailored solutions for your exact specifications.

✔ Reliable Logistics & Packaging – Secure and timely delivery worldwide.

✔ ISO-Certified Quality – ISO 9001:2015, ISO 14001:2015, and OHSAS 45001:2018 certified.

FAQS

Q1: What makes DRL-140 Low Creep Brick ideal for steel production?

A1: Its high creep resistance, thermal stability, and exceptional chemical durability make it perfect for extreme steel manufacturing environments.

Q2: How does this product reduce maintenance costs?

A2: The high strength and resistance to corrosion minimize brick replacements, cutting down on maintenance costs and downtime.

Q3: Can DRL-140 be customized for specific requirements?

A3: Yes! We offer custom dimensions and specifications to meet your unique operational needs. Contact us for tailored solutions.

Get a Free Quote Today!

Looking for a high-performance DRL-140 Low Creep Brick to enhance your steel manufacturing process? Contact us now for a competitive wholesale quote:

📧 Email: baiqiying@tianyunc.com

YOU MAY LIKE