Zirconium SiC Brick

Raw Material:Industrial alumina powder and selected zircon sand

Advantage:Sintered zirconia corundum bricks are highly resistant to molten glass erosion,good thermal shock resistance.

Application:It is mainly used in the upper space of the glass kiln that is not in contact with the molten glass, as well as the slide rail of the rolling furnace

Zirconium SiC Brick Manufacturer & Supplier

TianYu Refractory Materials Co., LTD specializes in manufacturing high-performance Zirconium SiC Bricks, offering exceptional quality and reliable solutions for the steel industry. With over 20 years of experience, we provide refractory products designed to withstand extreme conditions, delivering outstanding fire resistance, wear resistance, and chemical stability.

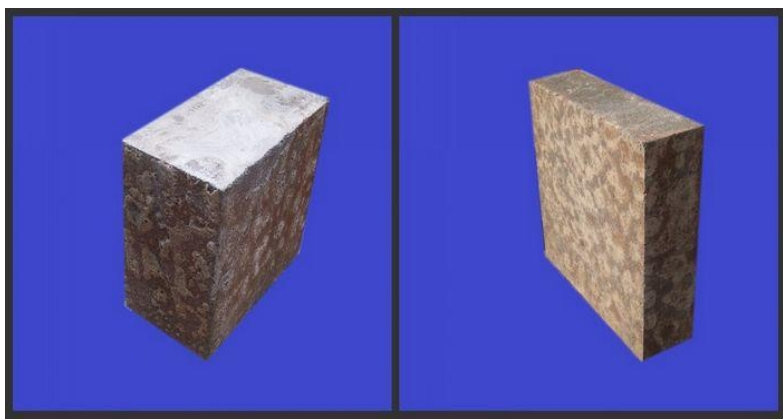

Zirconium SiC Brick Introduction

Zirconium SiC brick often integrate zirconium dioxide (ZrO₂) or zirconium-based additives with silicon carbide (SiC). The inclusion of zirconium compounds improves the material’s resistance to thermal shock and corrosion, while SiC provides high thermal conductivity and structural integrity311. For example, oxide-bonded SiC and reaction-sintered SiC are common formulations used in refractory applications.

Key Attributes

| Property | Description |

|---|---|

| Fire Resistance | Withstands extremely high temperatures, up to 1700°C. |

| Strength | High compressive strength and crack resistance. |

| Chemical Stability | Resists molten metal and slag erosion. |

| Dimensional Accuracy | Precise shaping for easy installation. |

| Cost-effectiveness | Offers long service life, reducing overall maintenance costs. |

Product Features

Superior Temperature Resistance: Capable of withstanding extreme temperatures, Zirconium SiC Brick maintains structural integrity even under intense heat.

Enhanced Durability: The brick’s high strength ensures resistance to pressure, impact, and wear, extending its lifespan in heavy-duty industrial applications.

Corrosion and Erosion Resistance: Offers excellent resistance to the chemical attacks from molten metals and slag, making it ideal for steel manufacturing.

High Dimensional Precision: Manufactured to meet precise measurements, ensuring seamless integration into various industrial systems.

Production Process

Our products are produced using advanced techniques that blend zirconium and silicon carbide for optimal performance. The manufacturing process involves careful selection of raw materials, precise molding, and high-temperature firing to ensure the highest quality. Each brick undergoes rigorous quality control and testing to meet international standards, providing our customers with consistent, reliable products.

Applications

Zirconium SiC Bricks are primarily used in the following applications within the steel industry:

Blast Furnaces: Protecting furnace walls from extreme heat and slag erosion.

Hot-Blast Stoves: Ensuring long-lasting performance in high-temperature environments.

Pig-Iron Transportation Systems: Used in Iron Ladles and Torpedo Cars to transport molten metal safely.

Tapping Holes: Utilized in the tap-hole assembly for efficient pig iron flow.

Why Choose Us

Unmatched Durability: Our products endure harsh industrial conditions, reducing maintenance costs and downtime.

Custom Solutions: We offer tailored solutions to meet the specific needs of your production process.

ISO Certified Quality: Our products are manufactured to meet the highest standards, with ISO 9001:2015, ISO 14001:2015, and OHSAS 45001:2018 certifications.

Technical Support: Our team of experts is available to provide you with ongoing support to ensure smooth integration and long-term performance.

FAQ

Q: What is the maximum temperature product can withstand?

A: It can withstand temperatures up to 1800°C, making them ideal for high-temperature applications in steel production.

Q: Are these bricks resistant to thermal shock?

A: Yes, it has excellent thermal shock resistance, ensuring they can withstand rapid temperature changes without cracking.

Q: What are the key advantages of product over other refractory materials?

A: The combination of high thermal conductivity, wear resistance, and chemical stability makes product a superior choice for steel manufacturing processes.

Q: Can I get customized sizes?

A: Yes, we offer customized sizes to meet the specific needs of your operations. Contact us for more details.

Contact Us

For more information or to place an order about Zirconium SiC Brick, feel free to contact us at [baiqiying@tianyunc.com].