High Alumina Mortar

Raw Material:high chamotte,soft clay or chemical bond.

Advantage:high refractoriness,strong thermal shock resistance,abrasion resistance,good work ability.

Application:It can be widely used in all kinds of industry furnaces with high alumina bricks, such as the construction of furnace roof, regenerative chamber, combustion chamber and other parts of hot-blast furnace, upper part and other parts of blast furnace, the repair of furnace top, furnace wall and other parts of industrial furnaces.

What is High Alumina Mortar?

High Alumina Mortar is a top-tier refractory material used extensively in the steel industry for its excellent thermal, chemical, and mechanical properties. With over 20 years of experience, TianYu Refractory Materials Co., LTD specializes in manufacturing and supplying high-quality refractories, including it, which plays a vital role in improving the operational efficiency and longevity of steelmaking furnaces and related equipment.

Key Attributes

| Attribute | Description |

|---|---|

| Alumina Content | ≥ 70% |

| Temperature Resistance | Up to 1600°C |

| Compressive Strength | High strength to withstand pressure and impact |

| Chemical Stability | Excellent resistance to slag and molten metal corrosion |

| Dimensional Accuracy | Precise dimensions for smooth installation |

| Durability | Long-lasting performance under harsh conditions |

| Application | Ideal for furnaces, ladles, and other high-temperature environments |

High Alumina Mortar Features

High Temperature Resistance: With a high alumina content, our product offers outstanding heat resistance, ensuring reliable performance in environments with temperatures up to 1600°C.

Durability & Longevity: Engineered for long-term performance, this mortar resists wear and tear, reducing maintenance costs for steel mills and foundries.

Chemical Stability: Its exceptional resistance to chemical erosion from molten metals and slag ensures long-lasting protection for steel production systems.

Easy Application: It is easy to apply and guarantees a precise fit with minimal shrinkage, ensuring a smooth and efficient installation process.

Production Process

Our product is produced using the latest technology in refractory manufacturing. The process includes:

Raw Material Selection: High-quality alumina materials are carefully selected to ensure superior properties.

Mixing & Grinding: The materials are mixed and ground to the optimal consistency for superior bonding strength.

Firing: The mortar is fired at high temperatures to enhance its strength and resistance properties.

Quality Control: Each batch undergoes rigorous quality control checks to meet the highest industry standards.

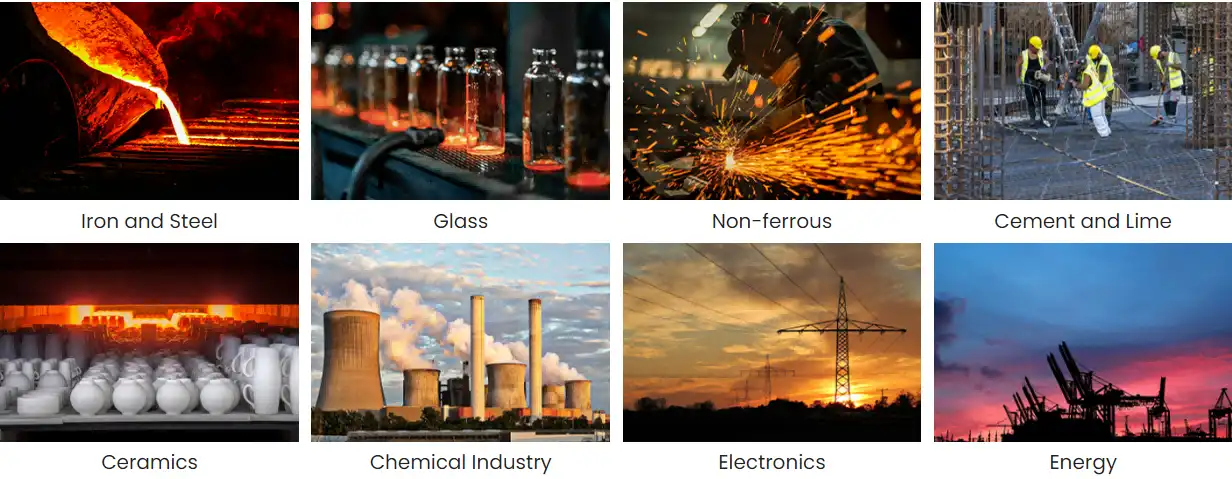

Applications

High Alumina Mortar is widely used in the steel industry, including:

Furnaces: For lining and repairing high-temperature steel furnaces.

Ladles: To enhance the durability of iron ladles and other molten metal containers.

Hot Blast Stoves: Ideal for use in blast furnaces where high thermal conductivity and wear resistance are essential.

Torpedo Cars: Used in the transportation of molten metal due to its resistance to high temperatures and wear.

Why Choose Us?

TianYu Refractory Materials Co., LTD has been a trusted name in the refractory industry for over two decades. Here’s why you should choose our product:

Quality Assurance: We are ISO 9001:2015 certified and maintain a rigorous quality control process to ensure every product meets high standards.

Expertise: With over 20 years of experience and a dedicated team of engineers, we offer tailored solutions and technical support to optimize your production processes.

Competitive Pricing: Our direct manufacturing capabilities allow us to offer cost-effective solutions without compromising on quality.

Logistics & Packaging: We provide efficient logistics and secure packaging to ensure your order arrives on time and in perfect condition.

Research & Development: Our in-house R&D center ensures that we stay at the forefront of innovation and deliver cutting-edge products.

FAQ

Q: What is the maximum temperature resistance of it?

A: Our product can withstand temperatures up to 1600°C.

Q: Can it be used for all types of furnaces?

A: Yes, it is suitable for various furnaces and high-temperature applications in the steel industry.

Q: How does it resist corrosion?

A: The material's high alumina content provides excellent resistance to slag and molten metal erosion.

Q: How long does the it last?

A:It offers excellent durability, reducing the frequency of repairs and maintenance in high-temperature environments.

Q: Do you offer technical support?

A: Yes, we offer comprehensive technical support to help with material selection, application, and troubleshooting.

Contact Us

Interested in our High Alumina Mortar or need more information? Feel free to get in touch with us at:

Email: baiqiying@tianyunc.com

We are here to provide solutions for your steel production needs!