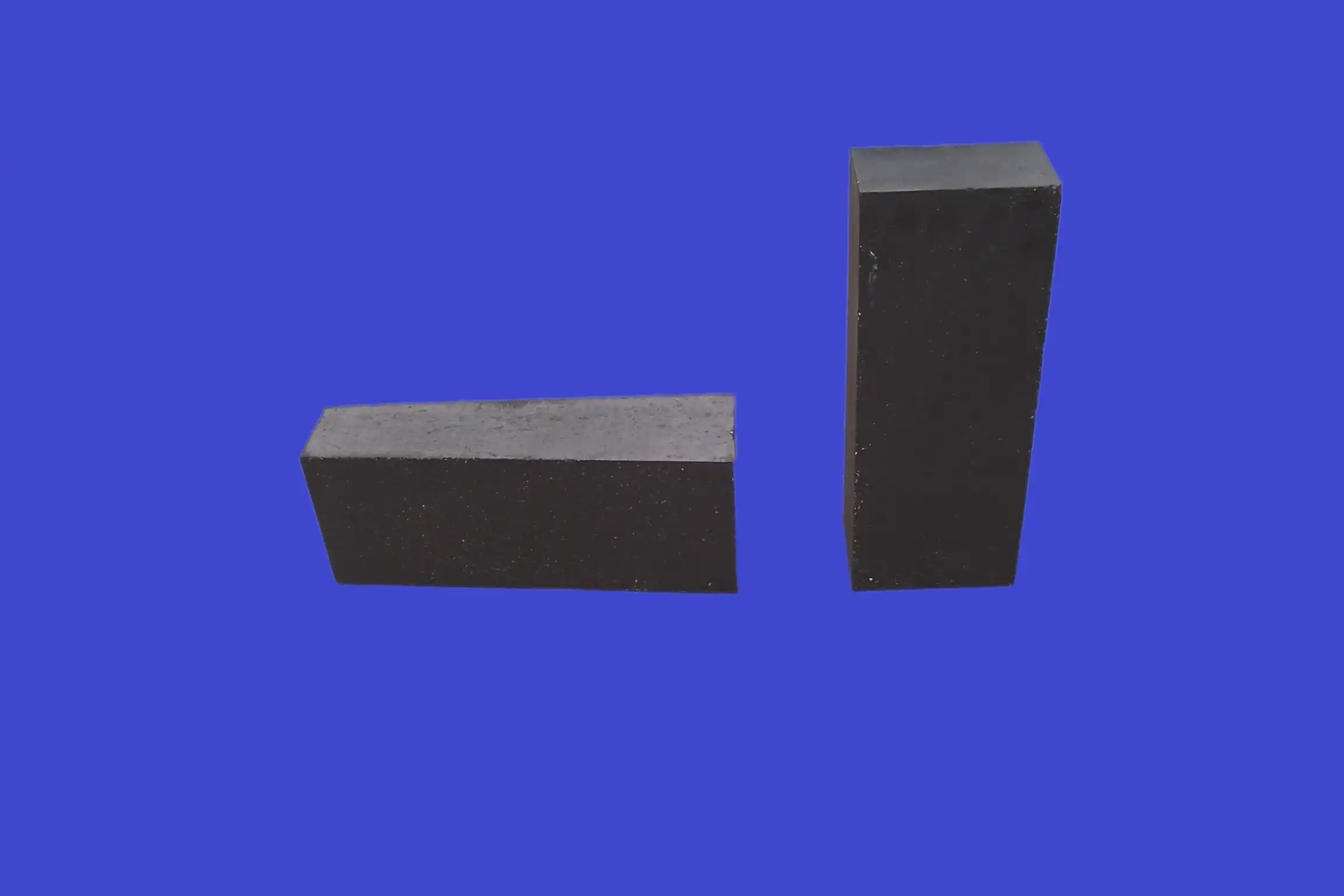

ASC Brick For Torpedo Car

Raw materials:fused corundum,graphite and silicon carbide with fixed carbon above 90%-95%

Advantage:The ASC brick has good thermal shock resistance,good abrasion resistance and good slag resistance.

Application:It is mainly used in the iron and steel industry, such as torpedo tanks, hot metal tanks, shakers, etc.

ASC Brick for Torpedo Car Manufacturer & Supplier

TianYu Refractory Materials Co., LTD is a trusted manufacturer and supplier of ASC Brick for Torpedo Car. With over 20 years of expertise in the steel industry, our ASC Brick combines unmatched durability, superior performance, and cost-effectiveness to meet your operational needs.

ASC Brick for Torpedo Car Introduction

The ASC Brick for Torpedo Car is specifically designed to handle the demanding conditions of transporting molten iron in steel manufacturing. Crafted with advanced refractory materials, these bricks offer exceptional fire resistance, wear resistance, and chemical stability. Whether you operate a large steel company or a smaller processing facility, our ASC Bricks provide a reliable solution to enhance operational efficiency and reduce maintenance costs.

Parameters

| Property | Specification |

|---|---|

| Material | Alumina-Silicon Carbide |

| Maximum Temperature | 1,800°C |

| Cold Crushing Strength | ≥60 MPa |

| Thermal Conductivity | High |

| Chemical Stability | Excellent |

| Wear Resistance | Superior |

| Dimensions | Customizable |

| Certification | ISO 9001:2015, ISO 14001:2015, OHSAS 45001:2018 |

Product Advantages

High Fire Resistance: Withstands extreme temperatures up to 1,800°C.

Superior Strength: High cold crushing strength ensures durability under heavy loads.

Chemical Stability: Resistant to molten metal and slag corrosion.

Customizable Dimensions: Tailored to meet specific installation needs.

Cost-Effective: Long service life minimizes maintenance and replacement costs.

Environmental Certification: Compliant with ISO environmental standards.

Flow of Production

We take pride in our state-of-the-art production process for ASC Brick For Torpedo Car:

Raw Material Selection: High-quality alumina and silicon carbide are sourced.

Mixing and Forming: Materials are precisely mixed and shaped using advanced technology.

Drying and Firing: Bricks are dried and fired in high-temperature kilns to ensure optimal properties.

Quality Testing: Each batch undergoes rigorous testing in our in-house lab for strength, stability, and dimensional accuracy.

Packaging: Final products are carefully packed to ensure safe transportation.

Applications

Torpedo Cars: Ideal for lining torpedo cars used in molten iron transportation.

Steel Plants: Enhances the performance and efficiency of steel production.

High-Temperature Environments: Suitable for various applications requiring high fire resistance and durability.

Why Choose us?

Experience: Over 20 years of expertise in the steel industry.

Quality Assurance: ISO-certified production processes and in-house testing facilities.

R&D Capabilities: Advanced R&D center with 21 patents.

Global Reach: Trusted by customers worldwide for first-class products and services.

Technical Support: Comprehensive pre- and post-sales technical assistance.

FAQ

Q: What is the typical service life of ASC bricks?

A: The service life ranges from 3 to 5 years, depending on usage conditions.

Q: Can the dimensions be customized?

A: Yes, we offer customizable dimensions to meet your specific requirements.

Contact Us

Ready to optimize your torpedo car operations? Get in touch with us today!

Email: baiqiying@tianyunc.com