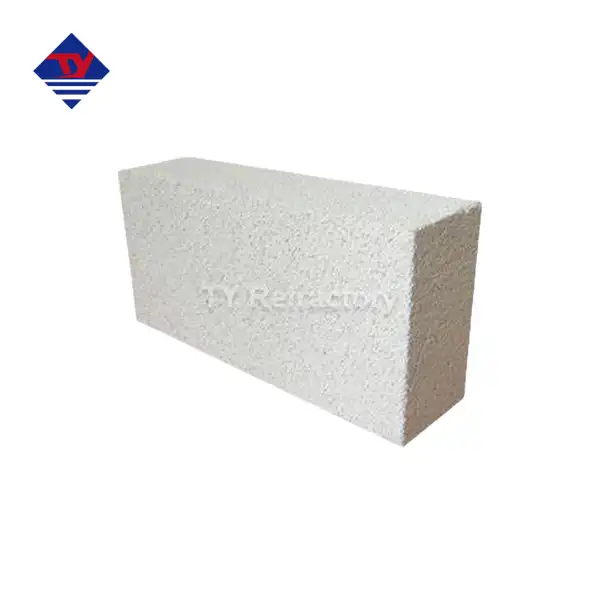

Special Magnesia Bricks

Raw Material:High-purity microcrystalline magnesia

Advantage:Low impurity content, low porosity, high strength and strong erosion resistance

Applicantion:Ideal refractories for Maerz kiln firing belts, sleeve lime kiln firing belts and combustion chambers.

Special Magnesia Bricks Manufacturer & Supplier

At TianYu Refractory Materials Co., LTD, we are dedicated to delivering high-performance Special Magnesia Bricks tailored to meet the demanding needs of the steel industry.

Introduction to Special Magnesia Bricks

Special Magnesia Bricks are engineered to withstand extreme temperatures, corrosive environments, and high-pressure applications, making them ideal for use in steel production and other high-temperature industries. Manufactured using premium magnesia and advanced technologies, these bricks offer exceptional durability, thermal stability, and chemical resistance. Whether you need customized shapes or standard designs, our products provide reliable solutions for your operational needs.

Parameters of Special Magnesia Bricks

| Property | Value |

|---|---|

| Magnesia Content | ≥ 90% |

| Bulk Density | 2.9-3.1 g/cm³ |

| Cold Crushing Strength | ≥ 50 MPa |

| Refractoriness | ≥ 1800°C |

| Apparent Porosity | ≤ 18% |

| Thermal Shock Resistance | Excellent (25 cycles) |

| Chemical Stability | High resistance to slag and metal corrosion |

Product Advantages

Our Special Magnesia Bricks are designed with your needs in mind. Here are some key advantages that set our products apart:

Superior High-Temperature Resistance: Designed to perform reliably in temperatures exceeding 1800°C.

Enhanced Durability: Low porosity and high strength ensure longer service life.

Corrosion Resistance: Withstands chemical erosion from molten metals and slags.

Dimensional Precision: Tailored designs to meet exact specifications for smooth installation.

Cost-Effectiveness: High performance coupled with competitive pricing ensures value for money.

Flow of Production

Raw Material Selection: Premium magnesia is sourced to ensure optimal quality.

Mixing and Shaping: Advanced techniques ensure uniform composition and precise shaping.

Drying: The bricks undergo controlled drying to minimize defects.

High-Temperature Firing: Fired in kilns at over 1500°C to achieve superior properties.

Quality Testing: Each batch is rigorously tested for strength, porosity, and thermal resistance.

Packaging and Delivery: Secure packaging ensures safe transport to your location.

Applications of Special Magnesia Bricks

Blast Furnaces: Ideal for lining to withstand high temperatures and corrosive environments.

Hot-Blast Stoves: Provides excellent thermal stability and resistance to thermal cycling.

Torpedo Cars: Protects against molten metal erosion during transportation.

Iron Ladles: Ensures longevity and resistance to thermal shocks in ladle applications.

Steel Ladles: Suitable for holding molten steel with enhanced durability.

Why Choose us?

Proven Expertise: Over two decades of experience in the steel industry.

Certifications: Accredited with ISO 9001:2015, ISO 14001:2015, and OHSAS 45001:2018.

R&D Excellence: A dedicated R&D center ensures innovative solutions.

Global Reach: Supplying top-tier products to customers worldwide.

Comprehensive Support: From product selection to technical assistance, we’ve got you covered.

Competitive Pricing: High-quality products at cost-effective rates.

FAQ

Q: What is the maximum temperature product can withstand?

A: It can withstand temperatures up to 1750°C, making them ideal for high-heat applications like blast furnaces and hot-blast stoves.

Q: How do I ensure the right brick for my application?

A: Our team of experts can guide you through selecting the right product based on your specific needs, ensuring optimal performance and cost-efficiency.

Q: What is the lead time for orders?

A: Our standard lead time is 3-5 weeks, depending on the quantity and customizations required.

Contact Us

For more information or to request a quote, feel free to reach out to us at baiqiying@tianyunc.com.

YOU MAY LIKE