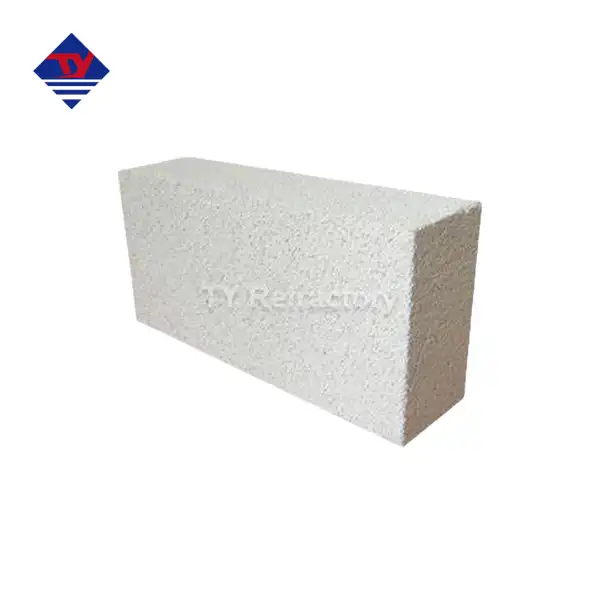

Mullite Brick

Raw material:mullite,65%-75%alumina,mullite mineral composition,lower alumina,glass and cristobalite.

Advantage: Good high temperature strength & Good thermal shock resistance,Resistance to most chemical attack & With excellent stability in acid metal slags,Resistance to oxidation and attack by furnace atmospheres.

Application:Mullite bricks are widely used in slag gasification furnaces, synthetic ammonia conversion furnaces, carbon black reactors, and refractory kiln furnaces, Furnace roof of hot blast stove, Furnace stack and bottom of blast furnace,Regenerative chamber of glass melting furnace and Ceramic high temperature furnace.

Mullite Brick Manufacturer & Supplier

TianYu Refractory Materials Co., LTD is a trusted name in the steel industry, offering high-performance Mullite Bricks designed for demanding applications.

Mullite Brick Introduction

Mullite Bricks are a premium choice for industries requiring materials with superior thermal performance, strength, and chemical stability. At TianYu, we specialize in manufacturing this product tailored to meet the rigorous demands of the steel industry, ensuring optimal performance in even the most challenging environments.

Technical Parameters

| Parameter | Specification |

|---|---|

| Al₂O₃ Content | 65%-75% |

| SiO₂ Content | 20%-30% |

| Bulk Density (g/cm³) | 2.6-3.0 |

| Cold Crushing Strength | ≥40 MPa |

| Refractoriness (℃) | ≥1650 |

| Thermal Conductivity | Low |

| Application Temperature | Up to 1700°C |

Product Advantages

High Fire Resistance: Withstand temperatures up to 1700°C, ensuring durability in extreme conditions.

Superior Strength: High cold crushing strength to endure heavy mechanical loads and impact.

Chemical Stability: Resists erosion by molten metal, slag, and other harsh substances.

Dimensional Accuracy: Precision-engineered to ensure seamless installation and optimal performance.

Cost-Effectiveness: Offers excellent value without compromising quality or performance.

Flow of Production

Raw Material Selection: High-purity mullite is carefully sourced and tested.

Mixing: Ingredients are blended to achieve the desired chemical composition.

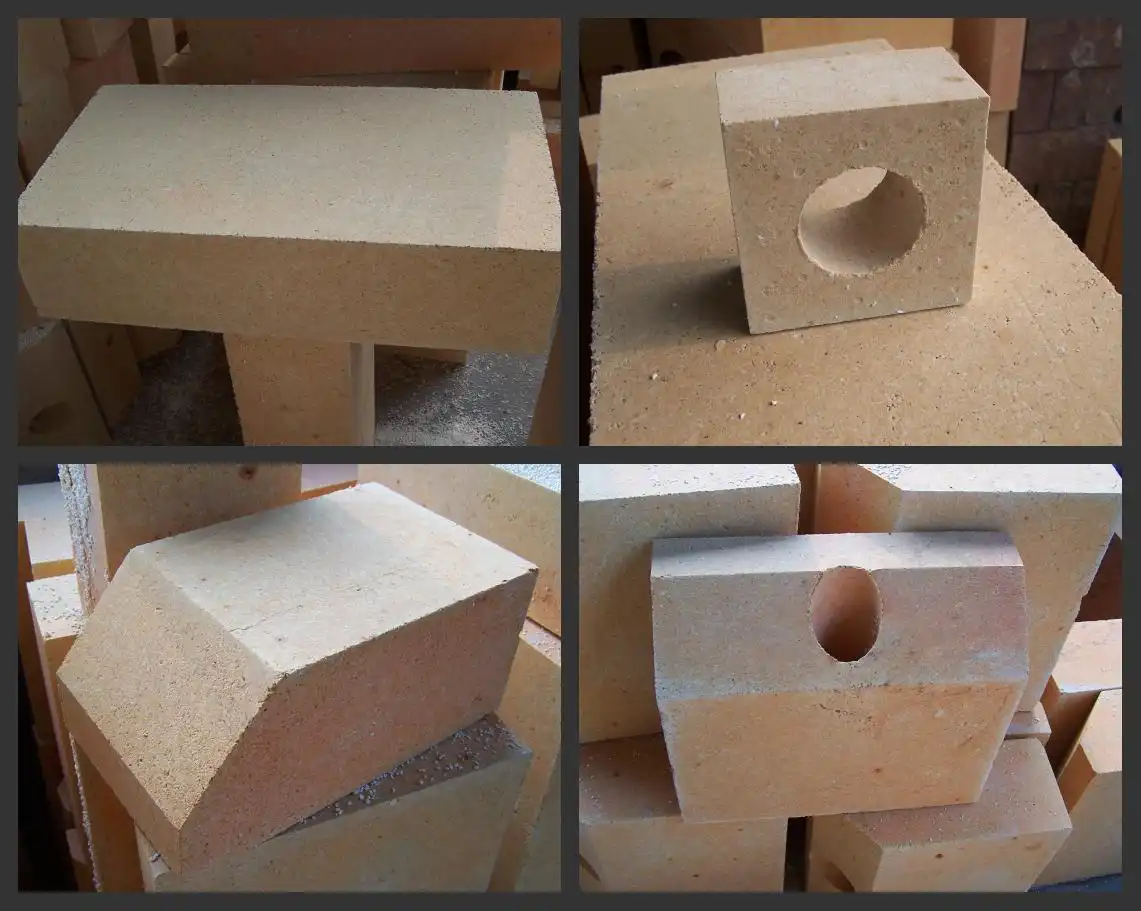

Shaping: Advanced molding techniques ensure dimensional accuracy.

Firing: Bricks are fired in high-temperature kilns to enhance strength and thermal resistance.

Quality Control: Each brick undergoes rigorous testing to ensure compliance with ISO 9001:2015 standards.

Applications

Our Mullite Brick is widely used in various applications within the steel industry, including:

Steel Industry: Blast furnaces, hot-blast stoves, and ladles.

Glass Industry: Regenerators and furnaces.

Cement Kilns: Rotary and vertical kilns.

Petrochemical Industry: Reactor linings and heat treatment furnaces.

Power Plants: Boiler linings and incinerators.

Why Choose us?

Proven Expertise: Over two decades of experience in refractory solutions.

Comprehensive Testing Facilities: In-house lab ensures top-tier product quality.

Certified Excellence: Accredited with ISO 9001:2015, ISO14001:2015, and OHSAS45001:2018 certifications.

Global Reach: Trusted by customers in the steel industry worldwide.

Innovative Solutions: Holder of 21 patents for refractory products and processes.

Contact Us

If you're looking for high-quality mullite bricks that meet the toughest standards of performance, reach out to us today. For inquiries, quotes, or technical support, contact us at baiqiying@tianyunc.com.

YOU MAY LIKE