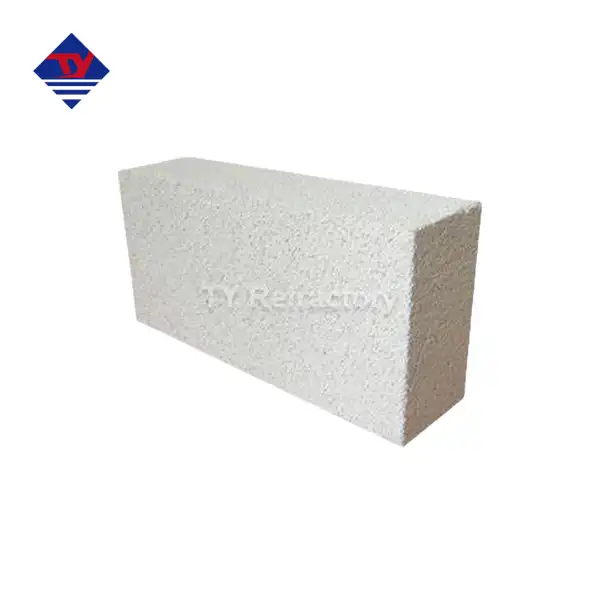

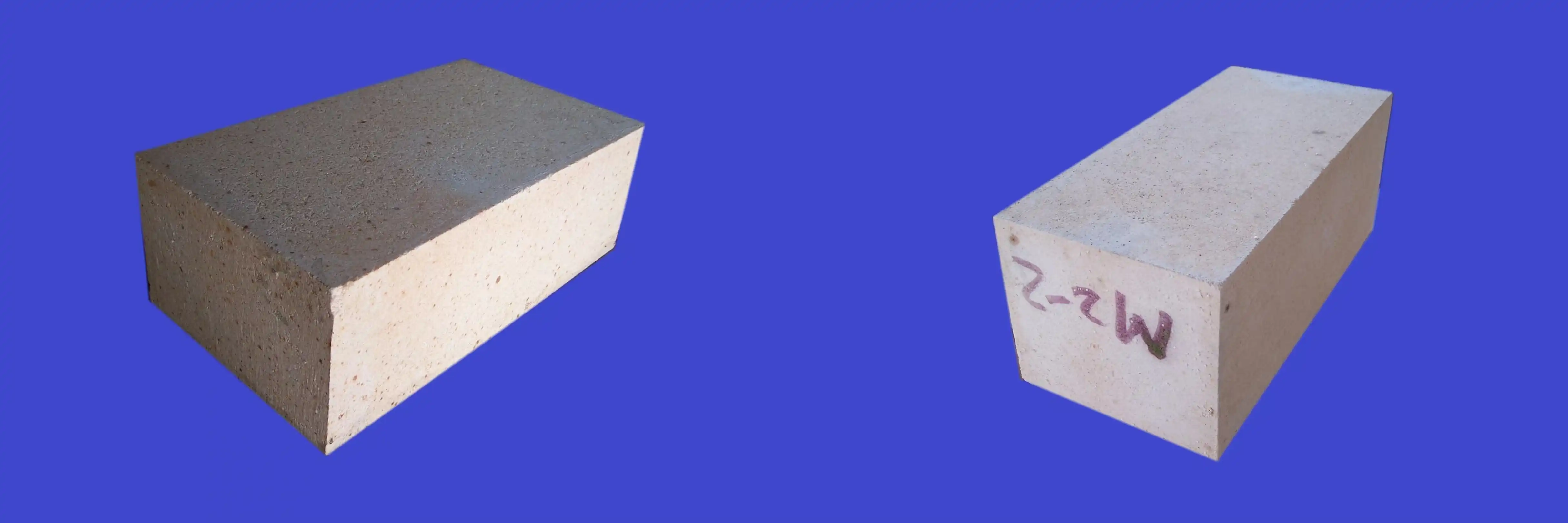

Corundum Mullite Brick For Lime Kiln

Raw Material:Pure mullite raw material synthesized from alumina powder and pure clay, bauxite or silica

Advantage:good thermal shock resistance,good corrosion resistance,good high temperature strength, high temperature creep resistance, thermal shock resistance and erosion resistance.

Application:It is mainly used in the petrochemical industry, large and medium-sized synthetic ammonia gasifier and magnetic material gas furnace materials, high-temperature industrial kiln supporting materials, etc

Corundum Mullite Brick For Lime Kiln Manufacturer & Supplier

TianYu Refractory Materials Co., LTD is a leading manufacturer and supplier of high-quality Corundum Mullite Brick For Lime Kiln. Our products are renowned for their exceptional performance in high-temperature applications.

Premium Corundum Mullite Brick for Lime Kiln – Manufacturer & Global Supplier

TianYu Refractory Materials Co., LTD proudly presents our premium Corundum Mullite Brick for Lime Kiln applications. With over 20 years of industry expertise, we manufacture and supply refractory bricks that meet the rigorous demands of high-temperature and corrosive environments. Designed for durability and engineered for excellence, our products are the trusted choice for global wholesale buyers seeking reliable, long-lasting refractory solutions.

Product Overview

Our Corundum Mullite Brick for Lime Kiln is a specialized refractory material that combines the unique benefits of corundum and mullite. This advanced brick is meticulously engineered to provide:

Exceptional High-Temperature Performance: Withstand extreme heat, thermal shocks, and aggressive chemical environments.

Outstanding Durability: Robust strength and crack resistance ensure prolonged service life even under continuous mechanical and thermal stress.

Superior Chemical Stability: Ideal for lime kiln applications where exposure to corrosive slag and molten materials is common.

Each brick is produced using state-of-the-art techniques and stringent quality controls, ensuring that every unit delivers optimal performance and precise dimensional accuracy.

Technical Specifications

| Parameter | Value |

|---|---|

| Material Composition | High-purity Corundum & Mullite |

| Bulk Density | 2.6 g/cm³ |

| Porosity | ≤ 25% |

| Refractoriness | Up to 1750°C |

| Cold Crushing Strength | ≥ 60 MPa |

| Thermal Shock Resistance | Excellent |

| Resistance to Slag & Metal | High |

Key Advantages

High Fire Resistance: Proven ability to maintain integrity in high-temperature environments.

Unmatched Strength and Durability: Engineered to endure high pressures and thermal cycling, reducing downtime and maintenance costs.

Chemical Resilience: Resistant to corrosive chemicals, molten metal, and slag, making it ideal for challenging lime kiln conditions.

Precise Dimensional Accuracy: Manufactured to exact specifications for seamless installation and optimal performance.

Cost-Effective: Delivers exceptional value with competitive pricing without compromising on quality.

Our Production Process

At TianYu, we adhere to a comprehensive, quality-focused production process:

Raw Material Selection: We source only the finest high-purity corundum and mullite to ensure product excellence.

Advanced Mixing & Forming: Our proprietary blending techniques and precision molding technology guarantee a homogeneous and robust product.

Controlled Drying & Firing: Each brick is dried and fired in state-of-the-art kilns to achieve maximum refractoriness and structural integrity.

Rigorous Quality Control: Every brick undergoes extensive testing against strict performance standards.

Secure Packaging & Delivery: We ensure that every shipment is carefully packaged to maintain product quality during transit.

Applications

Our Corundum Mullite Bricks are ideal for various high-temperature industrial applications, including:

Lime Kilns: Optimal for lining rotary lime kilns in steel production.

Cement Production: Reliable high-temperature lining for rotary cement kilns.

Glass & Ceramic Furnaces: Provides superior heat resistance for demanding furnace operations.

Steel Industry: Perfect for blast furnaces and other zones exposed to extreme temperatures and corrosive environments.

Why Global Buyers Choose TianYu

Expertise & Trust: Over two decades of experience in refractory materials ensures you receive products built on solid technical know-how.

Quality Assurance: Our products are ISO 9001:2015 certified, reflecting our unwavering commitment to quality.

Customization: We tailor brick sizes, shapes, and other specifications to meet your specific operational needs.

Dedicated Technical Support: Our experienced engineering team is ready to provide guidance and solutions to enhance your process efficiency.

Worldwide Reach: With a proven track record of serving global markets, we guarantee prompt delivery and competitive pricing, no matter where you are.

FAQ

Q: What is the expected service life of your bricks?

A: Our Corundum Mullite Bricks typically deliver a service life of 5 to 10 years, depending on operating conditions and maintenance practices.

Q: Can these bricks handle rapid temperature fluctuations?

A: Yes, they exhibit excellent thermal shock resistance, making them suitable for applications with frequent temperature changes.

Q: Are the bricks available in custom sizes?

A: Absolutely. We offer full customization to ensure the bricks perfectly meet your kiln specifications.

Q: How can I place an order or request additional technical details?

A: Simply reach out to us via email or phone. Our dedicated team is on standby to assist with inquiries, order placement, and technical support.

Ready to Elevate Your Refractory Performance?

Global Wholesale Buyers: Don’t wait! Experience the superior quality and reliability of our Corundum Mullite Bricks for your lime kiln applications. Contact us immediately to discuss your requirements and receive a prompt, personalized inquiry response.

Contact Information:

Email: baiqiying@tianyunc.com