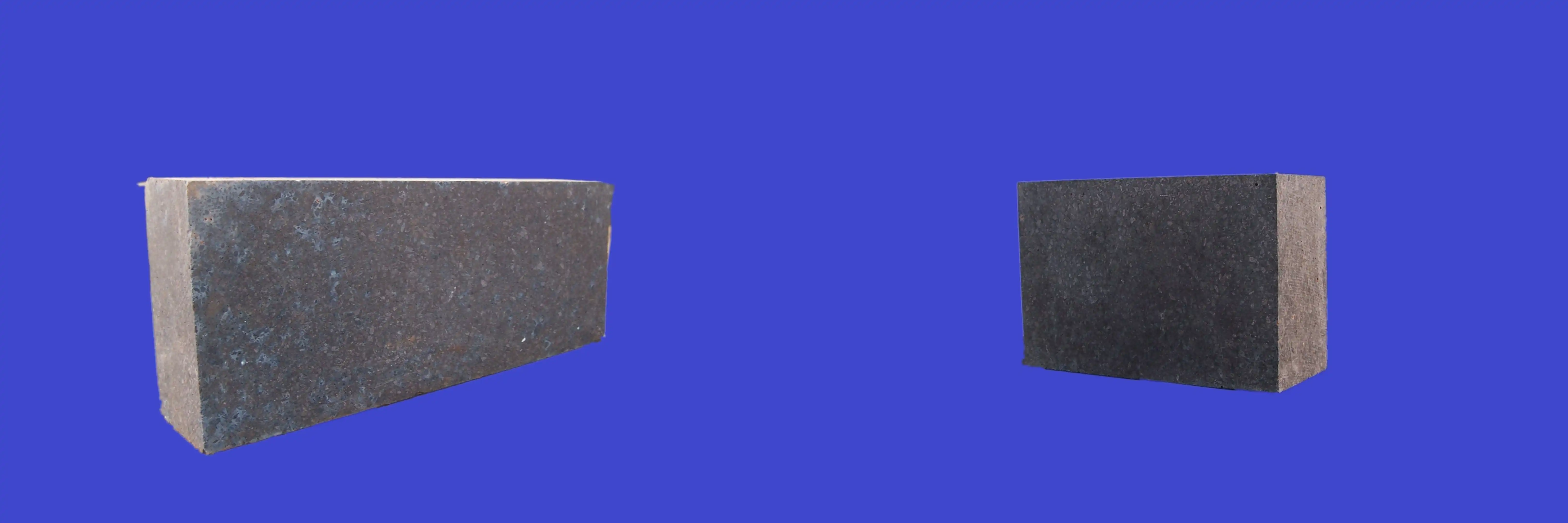

Compound Corundum Brick For Lime Kiln

Raw Material:corundum,silicon carbide,binder.

Advantage:high RUL,high strength,flexible,good slag resistance.

Application:Blast furnace cylinder, furnace bottom lining, calcium carbide furnace door

Compound Corundum Brick For Lime Kiln Manufacturer & Supplier

TianYu Refractory Materials Co., LTD is your trusted manufacturer and supplier of high-quality Compound Corundum Brick For Lime Kiln.

Compound Corundum Brick Introduction

TianYu’s Compound Corundum Brick For Lime Kiln is designed to withstand extreme thermal, chemical, and mechanical stresses inherent in lime kiln operations. Engineered with high-purity corundum and advanced production techniques, our bricks ensure superior fire resistance, exceptional wear resistance, and outstanding dimensional stability. Certified under ISO 9001:2015, ISO14001:2015, and OHSAS45001:2018, our products guarantee unmatched quality and reliability for long-term use.

Whether you are operating in the steel, chemical, or environmental industries, our product ensures efficiency and durability, making it the preferred choice for high-performance lime kiln linings.

Parameters

| Property | Value |

|---|---|

| Al2O3 Content | ≥93% |

| Bulk Density | ≥3.2 g/cm³ |

| Cold Crushing Strength | ≥100 MPa |

| Refractoriness | ≥1790°C |

| Thermal Shock Resistance | Excellent |

| Application Temperature | Up to 1700°C |

| Apparent Porosity | ≤10% |

Product Advantages

High Fire Resistance: With a refractoriness exceeding 1790°C, our bricks perform exceptionally well under high-temperature environments.

Exceptional Strength: High cold crushing strength ensures resistance to mechanical impact and pressure during operation.

Chemical Stability: Resists erosion from molten materials, slag, and gases, ensuring long service life.

Low Porosity: Enhanced durability and reduced slag penetration for extended performance.

Dimensional Precision: Ensures seamless installation and operational efficiency.

Cost-Effectiveness: Optimized production methods deliver high-performance bricks at competitive prices.

Flow of Production

Our production process for Compound Corundum Brick For Lime Kiln is meticulously designed to ensure the highest quality:

Raw Material Selection: High-purity corundum and other premium materials are carefully selected.

Mixing and Shaping: Advanced mixing and pressing techniques ensure uniform composition and precision.

High-Temperature Sintering: Bricks are sintered in state-of-the-art kilns to achieve optimal density and strength.

Quality Control: Rigorous in-house testing ensures compliance with international standards.

Packaging and Delivery: Secure packaging guarantees safe transportation and timely delivery.

Applications

Lime Kilns: Ideal for rotary and shaft lime kilns due to exceptional thermal resistance.

Steel Industry: Perfect for high-temperature zones in iron and steel processing.

Chemical Plants: Resists chemical erosion in high-stress environments.

Environmental Projects: Suitable for applications requiring durability under extreme conditions.

Why Choose Us?

Over 20 Years of Expertise: Serving the steel and refractory industry globally with a proven track record.

Certified Quality: ISO 9001:2015, ISO14001:2015, and OHSAS45001:2018 certifications ensure premium quality.

In-House R&D and Testing: Advanced facilities and a team of 20 engineers dedicated to product innovation and quality assurance.

Global Presence: Trusted by clients worldwide for reliable products and services.

Competitive Pricing: High-performance bricks at cost-effective rates.

Customized Solutions: Tailored products to meet specific customer needs.

FAQ

Q1: How long do compound corundum bricks last in a lime kiln?

A1: The lifespan of compound corundum bricks depends on factors like temperature, chemical exposure, and maintenance. On average, they last between 3 to 5 years, significantly reducing the need for frequent replacements.

Q2: Are these bricks customizable?

A2: Yes, we offer customization based on your specific requirements, including size, shape, and performance parameters.

Q3: How do you ensure consistent quality?

A3: Our bricks undergo strict quality control checks at every stage of production, from raw material selection to final testing. We maintain consistency through advanced manufacturing techniques and certified processes.

Q4: What is the delivery time for compound corundum bricks?

A4: The delivery time varies based on order volume, but typically, delivery is within 4 to 6 weeks after order confirmation.

Contact Us

For more information about Compound Corundum Brick for Lime Kiln or to request a quote, don’t hesitate to contact us at baiqiying@tianyunc.com. We look forward to helping you find the perfect solution for your high-temperature applications!