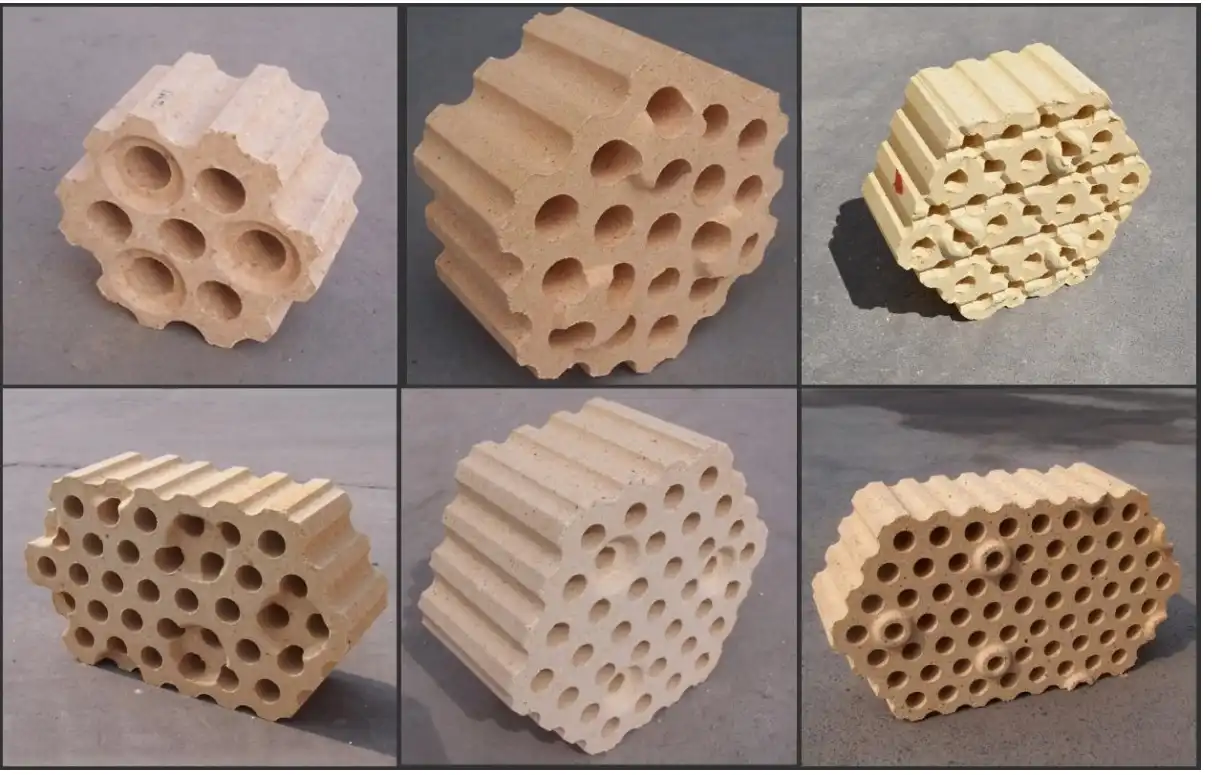

34 Holes Low Creep High Alumina Bricks

Material Type:clay bricks,high-alumina bricks, mullite bricks, sillimanite bricks and silica bricks

Advantage:Good volume stability,Good creep under load performance under high temperature,High bulk & density,Low porosity.

Application:It is mainly used for hot blast stoves.

34 Holes Low Creep High Alumina Bricks Manufacturer & Supplier

At TianYu Refractory Materials Co., LTD, we specialize in manufacturing 34 Holes Low Creep High Alumina Bricks, engineered to deliver unmatched durability, superior heat resistance, and long-lasting performance in steel, metallurgy, and cement industries.

✅ Factory Direct Pricing – Get high-quality refractory bricks at competitive wholesale rates

✅ Proven Performance – Trusted by global steel plants & high-temperature facilities

✅ ISO Certified Quality – Stringent quality control & advanced manufacturing technology

Why Choose Our 34 Holes Low Creep High Alumina Bricks?

🔹 Low Creep Rate (<1.2 ×10⁻⁴/50h) – Ensures structural integrity under extreme temperatures.

🔹 High Alumina Composition – Provides outstanding strength & chemical stability against slag and molten metal erosion.

🔹 Excellent Thermal Shock Resistance – Reduces cracking & extends service life.

🔹 Precision Manufacturing – Ensures dimensional accuracy for easy installation.

🔹 Customizable Specifications – Available in different sizes & compositions to fit your industrial needs.

📌 34 Holes Low Creep High Alumina Bricks Applications:

✔ Blast Furnaces – Exceptional resistance to high temperatures & metal penetration

✔ Hot Blast Stoves – 34 Holes Low Creep High Alumina Bricks enhance thermal efficiency & energy savings

✔ Steel Ladles & Torpedo Cars – Protects against slag erosion & thermal stress

✔ Industrial Kilns & Cement Rotary Kilns – Extends lining lifespan & reduces downtime

Technical Specifications

| Parameter | Value |

|---|---|

| Material | High Alumina |

| Porosity | 34 Holes |

| Creep Resistance | Low (<1.2 ×10⁻⁴/50h) |

| Max Operating Temp. | Up to 1800°C |

| Compressive Strength | ≥ 80 MPa |

| Bulk Density | 2.75 g/cm³ |

| Chemical Resistance | High resistance to slag & molten metal |

Our Advanced Manufacturing Process

🏭 Strict Raw Material Selection – High-purity alumina from top-tier suppliers

⚙️ Precision Forming & Molding – Ensures high dimensional accuracy

🔥 High-Temperature Firing (Up to 1800°C) – Enhances strength & durability

🔍 Rigorous Quality Testing – ISO-certified quality assurance before shipping

📦 Safe & Efficient Packaging – Fast global delivery with secure packaging

What Our Global Clients Say

🌟 “TianYu's 34 Holes Low Creep High Alumina Bricks significantly improved the lifespan of our blast furnaces, reducing downtime and saving costs!” – Steel Manufacturer, Germany

🌟 “Best refractory bricks we've used in our cement kilns! The thermal resistance is outstanding, and the pricing is unbeatable.” – Cement Plant, India

🌟 “Reliable supplier with excellent customer service. Quick response times and top-tier product quality.” – Metallurgical Factory, USA

FAQs

Q1: What is the minimum order quantity (MOQ)?

📌 MOQ starts from 10 tons. However, we offer flexible order sizes for trial orders. Contact us for details.

Q2: Can I get a free sample?

📌 Yes! We provide free samples for quality evaluation (freight charges apply).

Q3: How fast can you ship my order?

📌 Production time is 7-15 days, and shipping depends on destination. We ensure fast & reliable delivery worldwide.

Q4: Do you offer custom sizes or formulations?

📌 Absolutely! We provide customized refractory solutions tailored to your specific industrial needs.

Q5: How do I place an order?

📌 Simply send us an inquiry below, and our team will provide a quick quotation & delivery details!

Get a Fast Quote – Contact Us Today!

📧 Email: baiqiying@tianyunc.com

YOU MAY LIKE