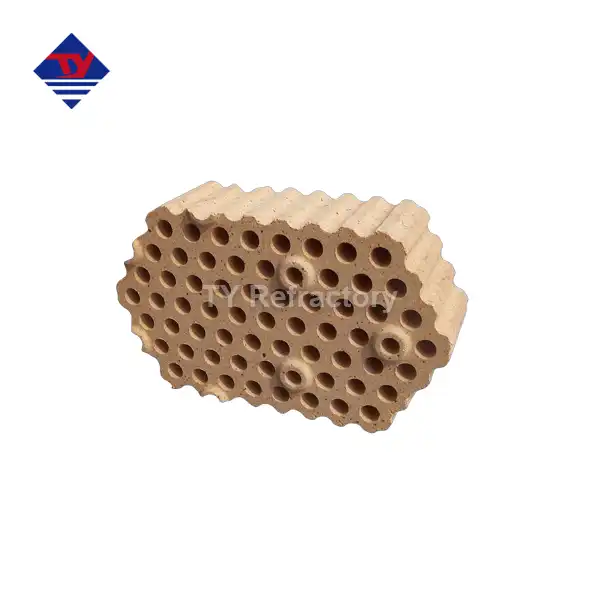

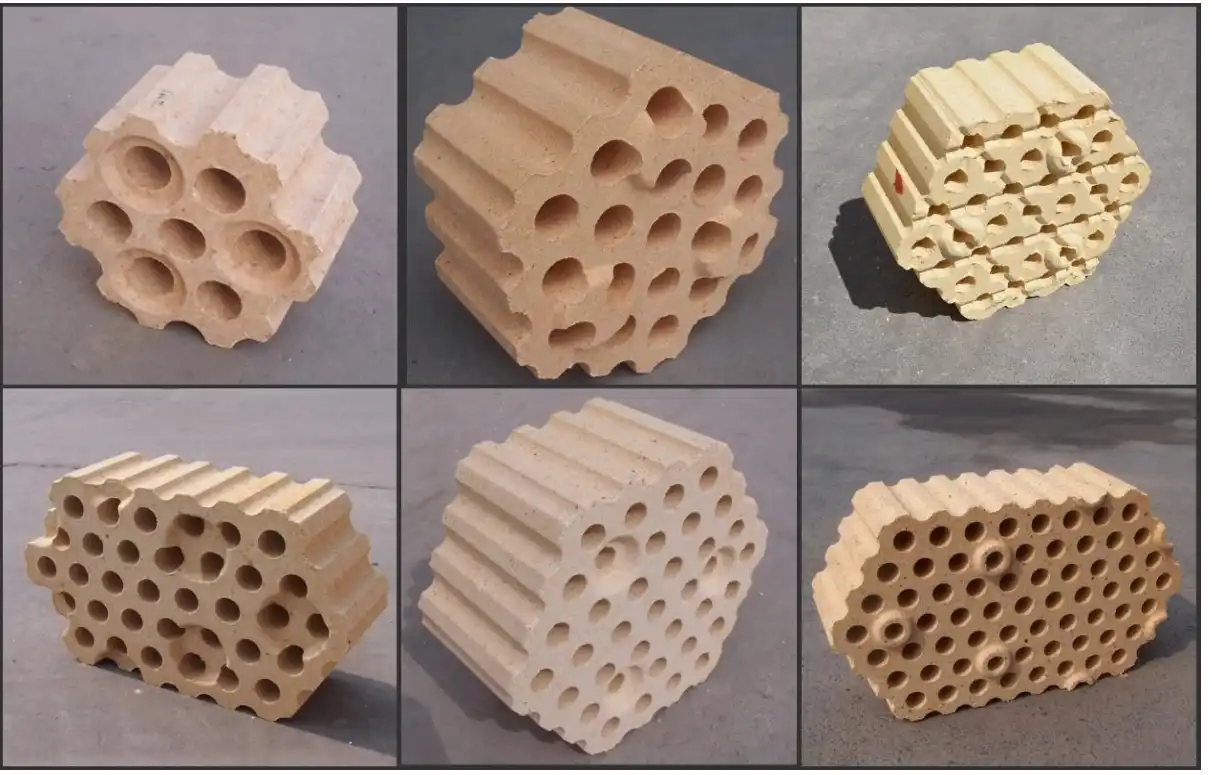

65 Holes Low Creep Fireclay Checker Bricks

Material Type:clay bricks,high-alumina bricks, mullite bricks, sillimanite bricks and silica bricks

Advantage:Strong resistance to high temperature gas erosion,excellent thermal shock resistance, strong resistance to thermal stress caused by temperature changes caused by cold and hot winds.

Application:It is mainly used in the upper and middle part of the heat storage chamber of the hot blast stove to store heat.

65 Holes Low Creep Fireclay Checker Bricks Manufacturer & Supplier

TianYu Refractory Materials Co., LTD is a leading global manufacturer specializing in premium refractory products. Our 65 Holes Low Creep Fireclay Checker Bricks are engineered for maximum durability, superior heat resistance, and exceptional efficiency in steel and metal industries.

Why Our 65 Holes Low Creep Fireclay Checker Bricks?

✅ Low Creep Properties – 65 Holes Low Creep Fireclay Checker Bricks maintains shape and strength under extreme heat conditions, ensuring long-term reliability.

✅ High Compressive Strength – Withstands intense pressure in blast furnaces and hot blast stoves.

✅ Superior Thermal Shock Resistance – Prevents cracking and failure in sudden temperature fluctuations.

✅ Outstanding Chemical Stability – Resists corrosion from molten metal and slag, extending lifespan.

✅ Custom Sizes & Fast Production – Tailored solutions for your specific industrial needs.

Technical Specifications

| Parameter | Value |

|---|---|

| Brick Type | 65 Holes Low Creep Fireclay |

| Material | High-Purity Fireclay |

| Compressive Strength | ≥ 40 MPa |

| Thermal Shock Resistance | Excellent |

| Density | 2.4 g/cm³ |

| Size (mm) | Customizable |

| Application Temperature Range | Up to 1,600°C |

Industries & Applications

🔹 Blast Furnaces – Ensures efficient heat transfer and reduced wear in critical zones.

🔹 Hot Blast Stoves – Provides unmatched performance in extreme high-temperature environments.

🔹 Iron Ladles & Torpedo Cars – Withstands direct contact with molten metal, reducing maintenance needs.

🔹 Steel Mills – 65 Holes Low Creep Fireclay Checker Bricks improves efficiency and longevity in high-stress production areas.

🔹 Looking for the best refractory solution? Get in touch for bulk pricing!

Production Process & Quality Assurance

🔍 Step 1: Raw Material Selection – We source high-purity fireclay for optimal performance.

🔍 Step 2: Precision Formulation & Mixing – Ensures consistent low creep properties.

🔍 Step 3: Advanced Shaping & Molding – Achieves perfect uniformity and accuracy.

🔍 Step 4: High-Temperature Firing – Strengthens the bricks for superior durability.

🔍 Step 5: Rigorous Quality Testing – Every batch is tested for thermal resistance, compressive strength, and chemical stability.

Why Choose TianYu Refractory Materials?

🌍 20+ Years of Expertise – Trusted by global clients in the steel and metal industries.

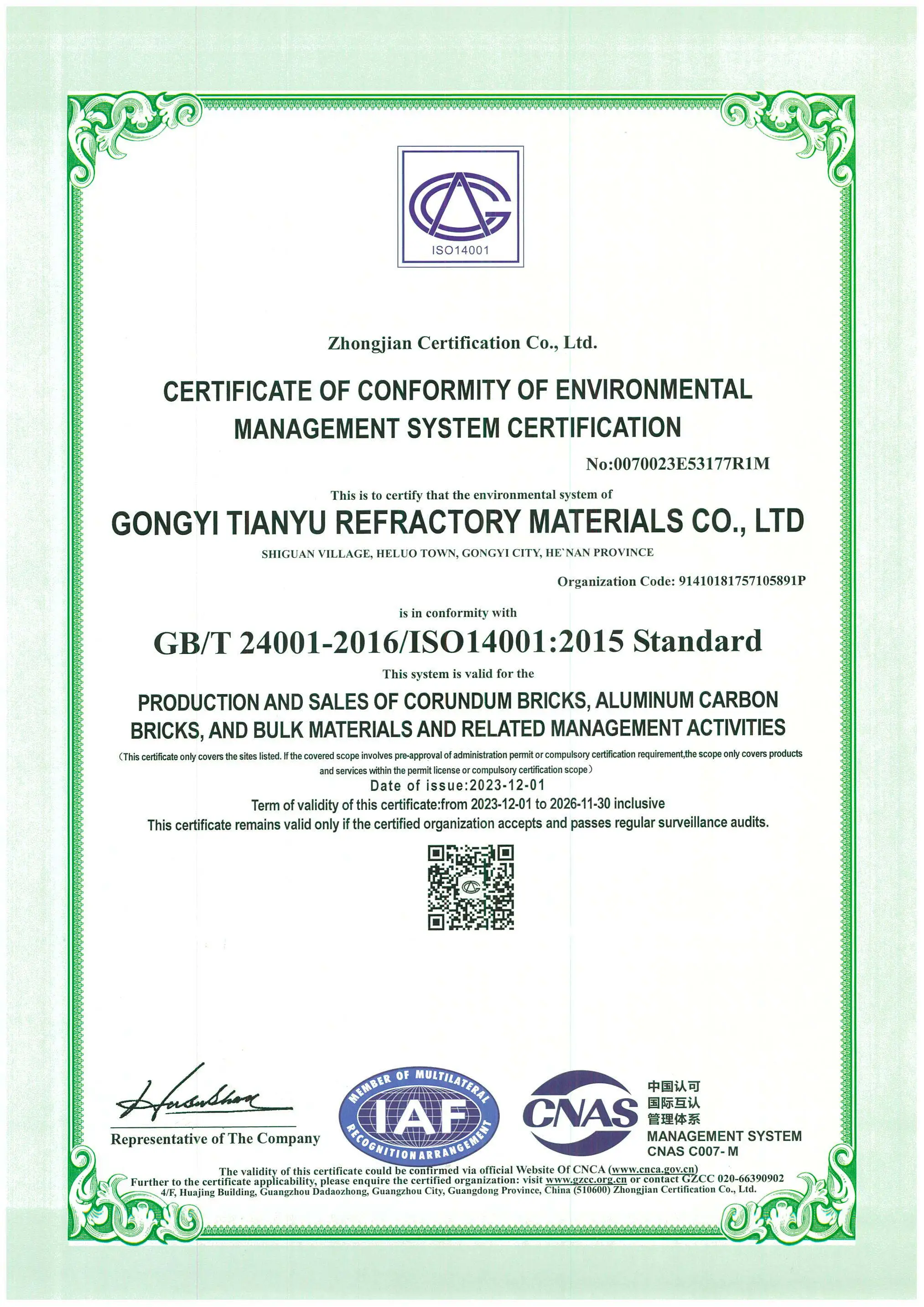

📜 ISO-Certified Quality – We guarantee top-tier products that meet international standards.

📦 Fast Global Shipping – Reliable logistics ensure on-time delivery worldwide.

🛠 Custom Solutions – Tailored refractory bricks to match your unique specifications.

💡 Technical Support – Our experts provide comprehensive guidance and assistance.

FAQ

❓ What makes these bricks ideal for high-temperature applications?

✔️ They are crafted from premium fireclay with low creep properties, ensuring durability under extreme heat and pressure.

❓ Can I order custom sizes for my application?

✔️ Yes! We provide custom dimensions to fit your exact requirements.

❓ How do these bricks help reduce maintenance costs?

✔️ With high strength and exceptional longevity, our bricks require fewer replacements, saving costs on repairs and downtime.

❓ What is the delivery time for bulk orders?

✔️ We offer fast production and worldwide shipping, ensuring you receive your order on time.

Get Your Quote Now!

📧 Email: baiqiying@tianyunc.com

YOU MAY LIKE