High Alumina Brick

Raw Material:bauxite,Al2O3

Advantage:Low high-temperature creep, strong erosion resistance, and good thermal shock stability,good resistance to slag.

Application:Low high-temperature creep, strong erosion resistance, and good thermal shock stability,good resistance to slag.

High Alumina Brick Manufacturer & Supplier

At TianYu Refractory Materials Co., LTD, we offer High Alumina Bricks designed for superior performance in extreme conditions.

Introduction to High Alumina Brick

High Alumina Bricks are a vital component in high-temperature applications, widely used in steel mills, blast furnaces, and industrial kilns. Engineered with a high alumina content, these bricks provide excellent resistance to heat, corrosion, and wear. Their exceptional durability and chemical stability make them ideal for demanding environments, helping you achieve cost-effective and efficient operations.

Parameters of High Alumina Brick

| Property | Specification |

|---|---|

| Alumina Content (%) | 45-90 |

| Apparent Porosity (%) | ≤20 |

| Bulk Density (g/cm³) | 2.3-3.0 |

| Cold Crushing Strength (MPa) | ≥50 |

| Refractoriness (°C) | ≥1790 |

| Thermal Shock Resistance (cycles) | ≥25 |

Product Advantages

Our High Alumina Brick is designed with your needs in mind. Here’s why it stands out:

High Fire Resistance: Withstand temperatures exceeding 1,790°C, ideal for extreme heat applications.

Exceptional Strength: High cold crushing strength ensures resistance to heavy mechanical loads.

Chemical Stability: Outstanding resistance to slag erosion and molten metal corrosion.

Dimensional Accuracy: Precision manufacturing guarantees easy installation and operational efficiency.

Cost-Effective: Long service life reduces maintenance and replacement costs.

Flow of Production

Raw Material Selection: Premium-grade bauxite and additives are sourced.

Mixing: Materials are homogenized to achieve consistent quality.

Molding: Advanced equipment ensures precision in size and shape.

Drying & Firing: Bricks are fired in high-temperature kilns for optimal strength and durability.

Quality Inspection: Rigorous testing ensures each brick meets industry standards.

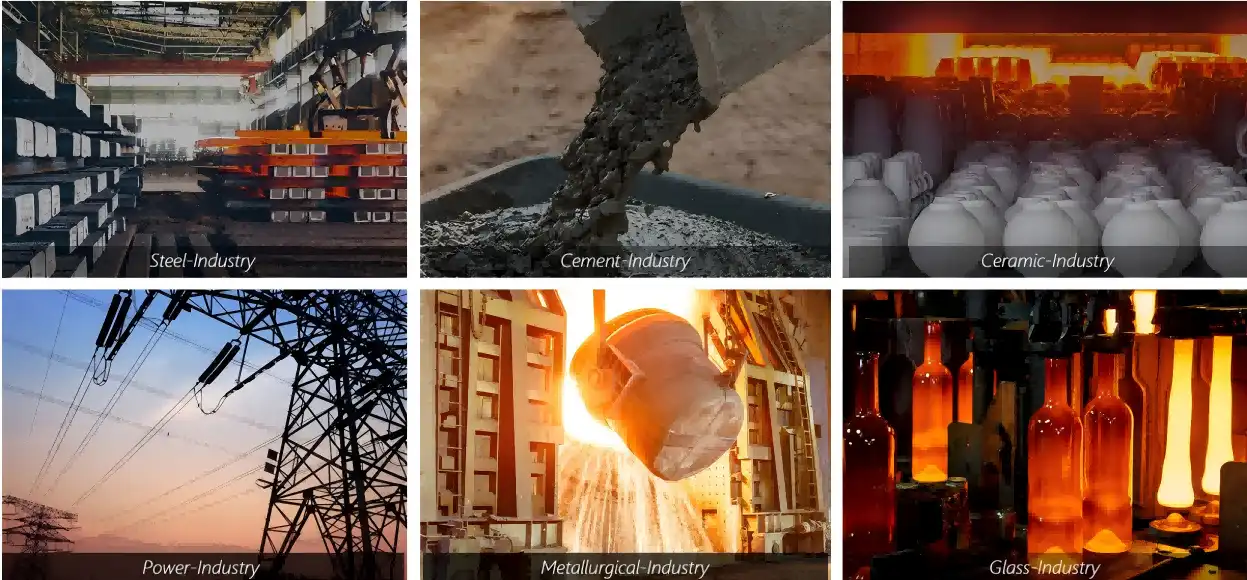

Applications

Blast Furnaces: Lining material for high-temperature zones.

Hot-Blast Stoves: Effective insulation and thermal management.

Steel Mills: Resistance to molten metal and slag.

Industrial Kilns: Durable and reliable for prolonged operations.

Petrochemical Industry: Protection against chemical erosion.

Why Choose us?

Proven Expertise: Over two decades in refractory manufacturing.

Comprehensive Testing: In-house labs ensure unmatched product quality.

Global Reach: Supplying to customers worldwide.

Certified Standards: ISO 9001:2015, ISO14001:2015, OHSAS45001:2018 accredited.

Innovative Solutions: 21 patents demonstrate our commitment to advancement.

FAQ

Q: What is the main advantage of it?

A: It offer excellent heat resistance, mechanical strength, and chemical stability, making them ideal for high-temperature applications.

Q: Can you customize the size and specifications?

A: Yes, we provide tailored solutions to meet your specific requirements.

Q: How do you ensure product quality?

A: We employ rigorous testing procedures and use only premium raw materials to guarantee superior performance.

Q: What is the typical service life of this product?

A: Service life varies depending on the application but generally offers extended durability, reducing maintenance costs.

Contact Us

If you need more information or wish to place an order for High Alumina Bricks, feel free to contact us at baiqiying@tianyunc.com.

YOU MAY LIKE