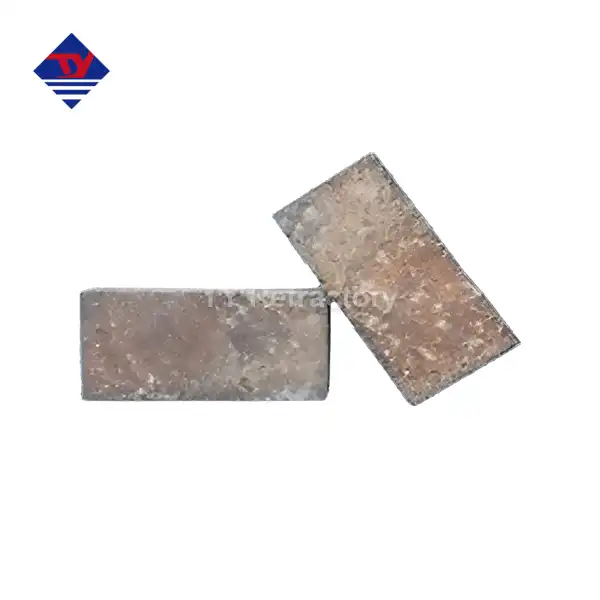

Magnesia Ramming Material

Raw Material:magnesia raw materials and additives

Advantage:Good thermal shock resistance,Convenient construction and time saving,Easy to be repaired.

Application:construction of lining of various kilns

Magnesia Ramming Material Manufacturer & Supplier

Discover top-notch Magnesia Ramming Material solutions from TianYu Refractory Materials Co., LTD—a trusted name with over 20 years of expertise in the steel industry. Benefit from our ISO-certified quality, innovative production processes, and customer-focused services.

Magnesia Ramming Material Introduction

Magnesia Ramming Material is an unshaped refractory material designed for use in high-temperature environments. It is primarily composed of high-purity magnesia and has excellent fire resistance, corrosion resistance, and thermal stability.

Parameters

| Property | Specification |

|---|---|

| Magnesia Content (%) | ≥ 95 |

| Bulk Density (g/cm³) | ≥ 2.9 |

| Cold Crushing Strength (MPa) | ≥ 30 |

| Linear Change Rate (%) | ≤ 0.3 (at 1600°C) |

| Grain Size (mm) | Customized (0-5 mm) |

| Installation Method | Ramming |

Product Advantages

High Fire Resistance: Capable of withstanding extreme temperatures exceeding 1600°C.

Excellent Corrosion Resistance: Protects against molten metal and slag erosion.

High Strength: Ensures durability under high pressure and impact.

Chemical Stability: Maintains integrity in aggressive environments.

Cost-Effectiveness: Offers exceptional performance at a competitive price.

Flow of Production

Raw Material Selection: Premium-grade magnesia is sourced to ensure quality.

Mixing and Proportioning: Advanced formulations are used to achieve optimal performance.

Granulation: The material is processed into specified grain sizes for uniformity.

Quality Testing: Rigorous in-house testing ensures compliance with ISO standards.

Packaging: Delivered in secure, moisture-proof packaging to preserve quality during transportation.

Applications

Our Magnesia Ramming Material is widely used in various applications within the steel industry, including:

Steelmaking Furnaces: Ideal for linings in electric arc furnaces, induction furnaces, and ladles.

Iron and Steel Casting: Used in critical areas requiring high thermal and mechanical stability.

Industrial Kilns: Suitable for high-temperature zones in kilns and rotary furnaces.

Why Choose Us?

Expertise & Experience: Over 20 years of focus on the steel industry.

Certified Quality: ISO 9001:2015, ISO 14001:2015 certifications.

Innovative R&D: 21 patents and cutting-edge technologies.

Global Reach: Trusted by customers in multiple countries.

Comprehensive Support: Dedicated technical assistance and after-sales service.

FAQ

Q: What is it?

A: It is a refractory material designed for high-temperature applications, primarily in the steel industry. It is used to line furnaces, kilns, and other high-heat equipment.

Q: What are the benefits of using product?

A: The main benefits include excellent fire resistance, high strength, corrosion resistance, and long-lasting performance in high-temperature environments.

Q: How do I choose the right it for my application?

A: Our technical team is available to assist you in selecting the right product based on your specific needs. We consider factors such as temperature resistance, chemical stability, and wear resistance to ensure optimal performance.

Q: Can I get a customized solution?

A: Yes, we offer customized solutions based on your requirements. Our R&D center works closely with clients to develop tailored products that meet specific application needs.

Contact Us

Ready to enhance your operations with high-quality Magnesia Ramming Material? Contact us today to learn more or request a quote!

Email: baiqiying@tianyunc.com