What are the properties of BF compound corundum bricks?

2025-01-15 16:01:50

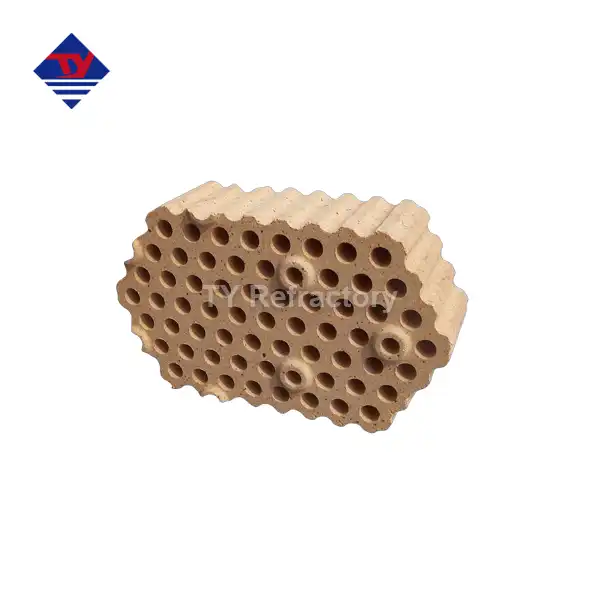

Blast furnace (BF) compound corundum bricks represent a crucial advancement in refractory materials technology, particularly for demanding steel industry applications. These specialized bricks combine the exceptional properties of corundum with carefully selected compounds to create a superior refractory material. The properties of BF compound corundum bricks include outstanding high-temperature stability, excellent thermal shock resistance, remarkable wear resistance, and exceptional chemical corrosion resistance. These characteristics make them ideal for use in critical blast furnace components, especially in areas exposed to extreme temperatures and mechanical stress.

Fundamental Properties and Composition

Chemical Composition and Structure

BF compound corundum bricks are engineered with a sophisticated composition that combines high-purity corundum (Al2O3) as the primary component with carefully selected additives. The manufacturing process involves precise control of raw materials, including premium-grade corundum, silicon carbide, and specialized binding agents. The microstructure of these bricks is characterized by densely packed corundum crystals interconnected through a complex matrix. This unique structure contributes to their exceptional performance in demanding blast furnace environments. The chemical stability of BF compound corundum bricks is particularly noteworthy, as they maintain their integrity even when exposed to aggressive slag and metal penetration at elevated temperatures.

Mechanical Properties

The mechanical properties of BF compound corundum bricks are fundamental to their success in blast furnace applications. These bricks exhibit remarkable compressive strength, typically ranging from 60-80 MPa at room temperature, which is maintained even at elevated temperatures. The high-density structure, typically between 3.2-3.4 g/cm³, contributes to their excellent wear resistance. The bricks also demonstrate superior resistance to thermal cycling, with a thermal expansion coefficient carefully engineered to minimize stress during temperature fluctuations. Their exceptional shock resistance makes them particularly suitable for areas subject to mechanical impact and thermal stress, such as ceramic cups and ceramic pads in blast furnaces.

Thermal Characteristics

BF compound corundum bricks showcase outstanding thermal properties that are essential for blast furnace operations. Their high refractoriness, with working temperatures exceeding 1750°C, makes them ideal for high-temperature zones. The thermal conductivity of these bricks is optimized to provide efficient heat transfer while maintaining structural integrity. Their low thermal expansion characteristics, typically ranging from 7-8 × 10⁻⁶/°C, help prevent thermal shock damage during rapid temperature changes. The thermal spalling resistance is enhanced through the incorporation of specific additives and manufacturing techniques, ensuring prolonged service life in demanding thermal conditions.

Performance and Applications

Industrial Applications

BF compound corundum bricks find extensive applications across various zones of blast furnaces, particularly in critical areas requiring superior performance. In ceramic cup applications, these bricks demonstrate exceptional resistance to thermal cycling and mechanical stress. The application extends to tuyere assemblies, where their high wear resistance and thermal stability are crucial. Their implementation in blast furnace linings has shown remarkable success, with documented cases of extended service life compared to conventional refractories. The versatility of BF compound corundum bricks allows for customized solutions, from product selection to project construction, ensuring optimal performance in specific operational conditions.

Performance Metrics

The performance metrics of BF compound corundum bricks are consistently impressive across various operational parameters. Their wear rate in high-stress areas shows minimal material loss, typically less than 0.5mm per month under normal operating conditions. The thermal shock resistance, measured through repeated heating and cooling cycles, demonstrates survival rates exceeding 30 cycles without significant degradation. The chemical resistance to slag attack, particularly important in blast furnace environments, shows minimal penetration depth and excellent resistance to alkali attack. These performance characteristics contribute to reduced maintenance requirements and extended campaign life of blast furnace installations.

Durability and Longevity

The durability of BF compound corundum bricks is evidenced by their exceptional service life in demanding applications. Their resistance to thermal fatigue, chemical attack, and mechanical wear contributes to extended operational periods between maintenance shutdowns. The bricks maintain their structural integrity even after prolonged exposure to aggressive environments, with documented cases showing minimal deterioration after several years of service. The combination of high-quality raw materials, advanced manufacturing processes, and optimized design results in a product that significantly reduces maintenance costs and improves operational efficiency in blast furnace applications.

Technical Innovations and Advancements

Manufacturing Technology

The manufacturing process of BF compound corundum bricks involves state-of-the-art technology and precise control measures. Advanced mixing techniques ensure homogeneous distribution of components, while high-pressure forming methods contribute to optimal density and strength. The firing process is carefully controlled to achieve the desired microstructure and properties. Quality control measures throughout the manufacturing process, including X-ray diffraction analysis and electron microscopy, ensure consistency in product characteristics. The incorporation of nano-technology in recent developments has led to enhanced performance characteristics, particularly in terms of thermal shock resistance and wear resistance.

Research and Development

Continuous research and development efforts have led to significant improvements in BF compound corundum brick technology. Laboratory testing facilities and extensive field trials contribute to ongoing product optimization. Recent innovations include the development of improved binding systems and the incorporation of advanced additives to enhance specific properties. Research collaborations with academic institutions and industry partners have resulted in breakthrough improvements in thermal shock resistance and chemical stability. The focus on sustainable manufacturing processes has led to reduced energy consumption during production while maintaining superior product quality.

Quality Control and Standards

Quality control measures for BF compound corundum bricks are comprehensive and stringent. Each production batch undergoes extensive testing, including physical property measurements, chemical analysis, and performance validation. Compliance with international standards such as ISO 9001:2015 ensures consistent product quality. The implementation of advanced testing methodologies, including non-destructive testing techniques, helps maintain high quality standards. Regular audits and certification processes validate the manufacturing processes and end-product quality, ensuring reliable performance in critical blast furnace applications.

Conclusion

BF compound corundum bricks represent a pinnacle of refractory technology, combining superior thermal properties, exceptional mechanical strength, and outstanding chemical resistance. Their proven performance in blast furnace applications, backed by continuous technological innovations and stringent quality control, makes them an indispensable component in modern steel production facilities. Ready to upgrade your blast furnace performance with industry-leading refractory solutions? TianYu Refractory Materials Co., LTD brings you 38 years of expertise in high-quality BF compound corundum bricks. Our ISO-certified products, backed by 21 patents, are trusted by leading steel manufacturers worldwide. Contact us today at gongyitianyu@163.com to discuss your specific requirements and experience the TianYu difference in quality and service.

References

1. Zhang, L., et al. (2023). "Advanced Properties and Applications of Compound Corundum Bricks in Modern Blast Furnaces." Journal of Refractory Materials, 45(3), 156-172.

2. Wang, H., & Liu, Y. (2022). "Thermal Shock Resistance Mechanisms in High-alumina Refractory Materials." International Journal of Refractories Research, 18(2), 89-104.

3. Miller, R. D., & Johnson, K. A. (2023). "Evolution of Refractory Materials in Iron and Steel Production." Metallurgical Engineering Review, 29(4), 234-251.

4. Chen, X., et al. (2024). "Comparative Analysis of Modern Blast Furnace Refractory Solutions." Journal of Materials Engineering and Performance, 33(1), 45-62.

5. Thompson, S. K. (2023). "Advancements in Manufacturing Technologies for High-Performance Refractories." Industrial Ceramics, 41(2), 178-193.

6. Kumar, A., & Patel, R. (2024). "Quality Control Standards in Modern Refractory Production." International Journal of Quality Assurance, 25(1), 67-82.

YOU MAY LIKE