Fire Clay Brick

Raw Material:kaolinite,clay clinker,refractory clay

Advantages:Clay bricks have good thermal performance and can withstand rapid temperature changes.

Applications:Mainly used in thermal boilers, glass melting furnaces, cement kilns, fertilizer gasification furnaces, blast furnaces, hot blast stoves, coke ovens, electric furnaces, and bricks for casting and pouring steel, etc.

Fire Clay Brick Manufacturer & Supplier

TianYu Refractory Materials Co., LTD is a trusted manufacturer and supplier, with over 20 years of expertise in producing high-performance Fire Clay Brick for the global steel industry. Our bricks offer superior durability, thermal resistance, and cost-effectiveness, making them the top choice for blast furnaces, hot-blast stoves, and other high-temperature applications.

Why Our Fire Clay Brick?

✅ Withstands Extreme Temperatures – Up to 1,790°C, ensuring longevity and efficiency.

✅ High Strength & Durability – Resists cracking, breaking, and pressure damage.

✅ Superior Chemical Stability – Resistant to molten metal and slag erosion.

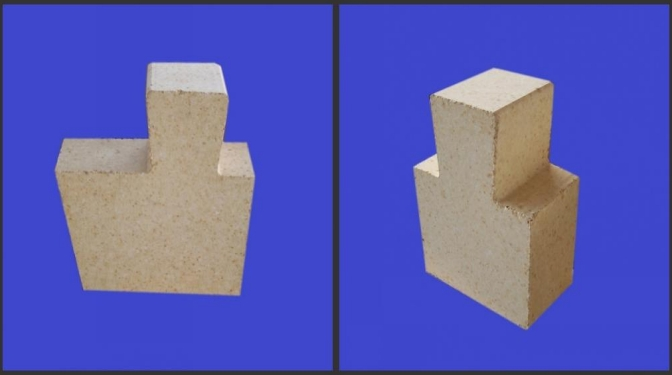

✅ Custom Sizes & Shapes – Tailored to fit your specific industrial needs.

✅ Factory-Direct Pricing – Get the best deals with bulk orders.

CERTIFICATE

Fire Clay Brick Technical Specifications

| Property | Specification |

|---|---|

| Bulk Density (g/cm³) | 2.2 - 2.4 |

| Cold Crushing Strength (MPa) | 30 - 50 |

| Refractoriness (°C) | 1,730 - 1,790 |

| Thermal Conductivity (W/mK) | 1.2 - 1.6 |

| Apparent Porosity (%) | 22 - 26 |

| Al₂O₃ Content (%) | 30 - 42 |

| Fe₂O₃ Content (%) | <2.5 |

Applications of Fire Clay Bricks

✔ Blast Furnaces – Ensures structural integrity & thermal efficiency.

✔ Hot-Blast Stoves – Provides stable and consistent performance.

✔ Iron Ladles & Torpedo Cars – Durable under extreme heat & mechanical stress.

✔ Kilns & Boilers – Ideal for high-temperature industrial operations.

✔ Foundries – Resistant to wear and corrosion during metal casting.

Our Manufacturing Process – Quality You Can Trust

1️⃣ Raw Material Selection – High-purity fire clay for premium quality.

2️⃣ Crushing & Mixing – Optimized blend for maximum strength & resistance.

3️⃣ Shaping & Molding – Precision-engineered for perfect dimensions.

4️⃣ Drying & Firing – High-temperature kilns for exceptional hardness.

5️⃣ Strict Quality Testing – Every batch meets ISO standards.

Why Choose TianYu Refractory Materials Co., LTD?

🌍 Global Supplier – Trusted by steel mills, foundries, and industrial plants worldwide.

🏭 Advanced Manufacturing – Cutting-edge R&D ensuring high performance.

📜 Certified Quality – ISO 9001:2015, ISO 14001:2015, OHSAS 45001:2018 accredited.

♻ Eco-Friendly Production – Sustainable & energy-efficient refractory solutions.

📦 Fast Delivery & Bulk Discounts – We fulfill large orders with competitive pricing.

FAQ

Q: What is the maximum temperature your Fire Clay Brick can withstand?

✅ Our bricks can endure up to 1,790°C, making them ideal for extreme industrial conditions.

Q: Do your Fire Clay Brick resist chemical corrosion?

✅ Yes, they are specially formulated to resist slag and molten metal erosion, ensuring longevity.

Q: Can you provide custom sizes?

✅ Absolutely! We manufacture tailor-made solutions based on your specifications.

Contact Us for Bulk Orders & Pricing

💼 Email: baiqiying@tianyunc.com

📞 Call us today and get a free quote!

🚀 Experience the highest-quality Fire Clay Brick – Order Now!