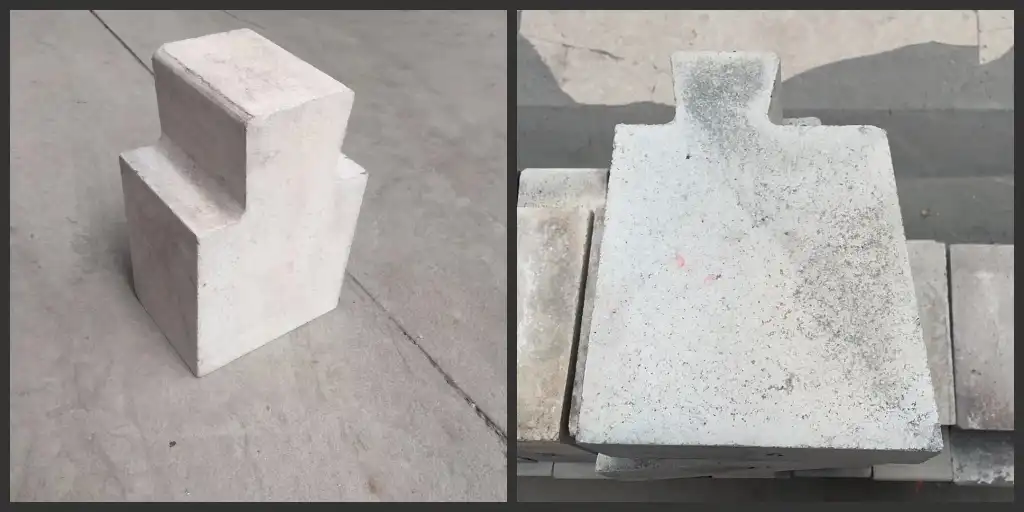

Silicon Nitride Brick

Raw material:Sintered magnesia and chrome ore

Advantages:High refractoriness, strong high-temperature strength, strong resistance to alkaline slag erosion, excellent thermal stability, and certain adaptability to acidic slag.

Application: Used to manufacture high-temperature bearings, metallurgical crucibles, and semiconductor zone melting boats in industries such as aviation, metallurgy, machinery, and semiconductors.

Silicon Nitride Brick Manufacturer & Supplier

At TianYu Refractory Materials Co., LTD, we specialize in manufacturing high-performance Silicon Nitride Brick designed to meet the rigorous demands of the steel industry. With over 20 years of expertise, we deliver durable, cost-effective, and innovative solutions to global clients.

Silicon Nitride Brick Introduction

Silicon Nitride Brick is a top-quality refractory material celebrated for its outstanding properties. It's perfect for situations where high temperatures and pressures are the norm.Made with cutting-edge technology, our products offer the best performance and last a long time, meeting the varied needs of steel plants and other industrial settings.

Parameters

| Property | Value |

|---|---|

| Chemical Composition | Si3N4 > 90% |

| Bulk Density | 2.70 g/cm³ |

| Cold Crushing Strength | > 150 MPa |

| Thermal Conductivity | 16-20 W/m·K |

| Operating Temperature | Up to 1,800°C |

| Porosity | < 16% |

Product Advantages

High Fire Resistance: Withstands extreme temperatures, ensuring structural integrity under harsh conditions.

Exceptional Strength: Superior mechanical strength resists cracking and wear over prolonged use.

Chemical Stability: Resistant to erosion from molten metals and slag, maintaining performance over time.

Low Thermal Expansion: Minimizes deformation under thermal cycling, enhancing Silicon Nitride Brick reliability.

Cost-Effective: Optimized for durability and longevity, reducing maintenance costs and downtime.

Flow of Production

Raw Material Selection: High-purity silicon nitride is sourced to ensure consistent quality.

Mixing & Shaping: Advanced mixing techniques and precision molding create uniform bricks.

Sintering: High-temperature kilns ensure optimal densification and strength.

Quality Inspection: Each batch undergoes rigorous testing to meet industry standards.

Packaging: Carefully packed to prevent damage during transit, ensuring safe delivery.

Applications

Blast Furnaces: Used as lining materials to withstand intense heat and chemical reactions.

Hot-Blast Stoves: Ideal for high-temperature zones due to their excellent thermal stability.

Steel Ladles and Torpedo Cars: Provides wear and corrosion resistance for efficient molten metal transportation.

Kilns and Furnaces: Applicable in industrial furnaces requiring high thermal shock resistance.

Why Choose us?

Proven Expertise: Over two decades of experience in refractory materials.

Certified Quality: Accredited with ISO 9001:2015, ISO14001:2015, and OHSAS45001:2018 certifications.

Innovative Solutions: Holder of 21 patents, ensuring cutting-edge technology.

Customer-Centric Approach: Tailored solutions and exceptional after-sales support.

Global Reach: Trusted by steel plants worldwide for premium refractory products.

FAQ

Q1: What makes it different from other refractory materials?

A1: It have superior thermal shock resistance and corrosion resistance, making them ideal for environments exposed to molten metal and slag.

Q2: What is the typical lifespan of product?

A2: With proper installation and maintenance, these bricks can last for many years, significantly reducing replacement and maintenance costs.

Q3: How do you ensure product quality?

A3: We have in-house testing facilities and a dedicated R&D center to maintain stringent quality standards.

Q4: What industries can benefit from Silicon Nitride Brick?

A4: Primarily used in the steel industry, they are also suitable for other high-temperature industrial applications.

Contact Us

For more information about Silicon Nitride Brick or to request a quote, feel free to contact us:

Email: baiqiying@tianyunc.com