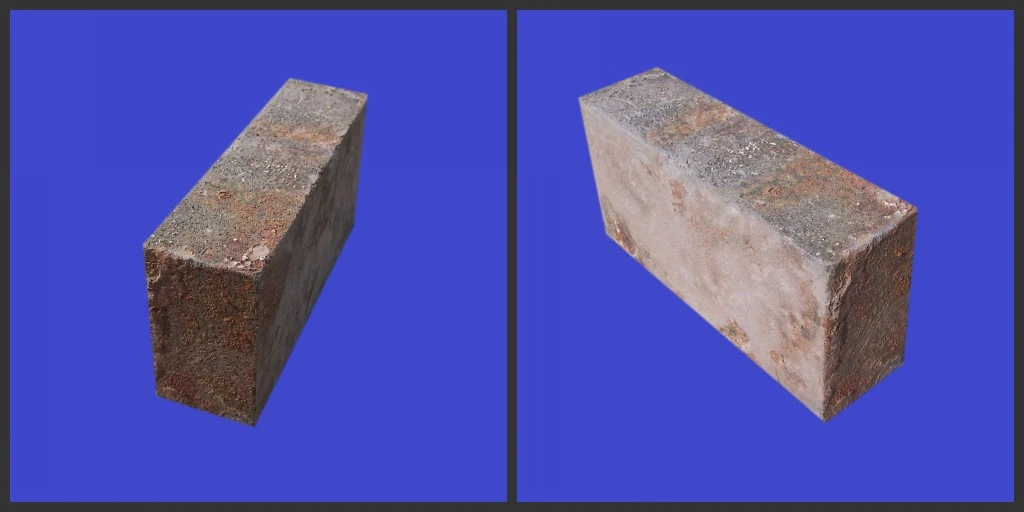

Silicon Carbide Brick SiC Brick

Raw Material:Black Silicon Carbide(SiC content > 96%)

Advantages:high-temperature resistance,high mechanical strength,high thermal conductivity,low thermal expansion,good wear resistance and corrosion resistance.

Application:In steel smelting, it can be used for ladle lining, nozzle, plug, blast furnace bottom and belly, tapping trough, converter and electric furnace tapping port

Silicon Carbide Brick SiC Brick Manufacturer & Supplier

Looking for Silicon Carbide Brick SiC Brick to boost your industrial efficiency and cut down operational costs? With over 20 years of expertise, TianYu Refractory Materials Co., LTD is your trusted manufacturer & supplier, delivering high-strength, high-temperature-resistant, and cost-effective SiC Bricks tailored to your needs.

Why Choose TianYu SiC Bricks?

✔ Unmatched Durability – Withstands extreme heat, mechanical stress, and corrosive environments

✔ High Thermal Conductivity – Ensures superior energy efficiency

✔ Excellent Wear & Corrosion Resistance – Extends service life and reduces downtime

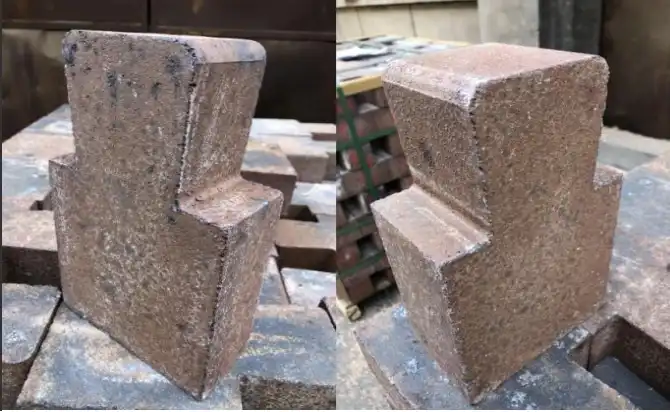

✔ Precision Engineering – Ensures accurate dimensions for seamless installation

✔ Direct Manufacturer Pricing – Get factory-direct rates with no middlemen

Specifications

| Parameter | Specification |

|---|---|

| Silicon Carbide (SiC) Content | ≥ 90% |

| Bulk Density | 2.6-3.0 g/cm³ |

| Cold Crushing Strength | ≥ 100 MPa |

| Refractoriness | ≥ 1700°C |

| Thermal Conductivity | High |

| Apparent Porosity | ≤ 15% |

| Alkali Resistance | Excellent |

Where Can You Use Our Silicon Carbide Brick SiC Brick?

Our high-performance Silicon Carbide Brick SiC Brick is the go-to choice for demanding industrial applications: ✅ Blast Furnaces – Maximizes efficiency and lifespan

✅ Hot-Blast Stoves – Provides outstanding thermal insulation

✅ Steel Ladles & Torpedo Cars – Resists extreme thermal and chemical exposure

✅ Petrochemical & Chemical Processing – Ensures stable operation in harsh conditions

✅ Power Plants & Incinerators – Enhances efficiency and minimizes maintenance costs

Our Advanced Production Process

Step 1: High-purity Silicon Carbide selection

Step 2: Precision blending for optimal material properties

Step 3: High-precision molding for dimensional accuracy

Step 4: High-temperature sintering for maximum strength

Step 5: Stringent quality control for guaranteed reliability

Client Testimonials – Trusted by Global Buyers

✔ "TianYu’s Silicon Carbide Brick SiC Brick significantly improved our furnace performance and reduced downtime. Highly recommend!" – Industrial Furnace Manufacturer, Germany

✔ "Best SiC Bricks we’ve used – durable, cost-effective, and reliable." – Steel Plant Buyer, USA

Get the Best SiC Brick Deals Now!

Don’t settle for low-quality refractory materials! Contact us today for competitive wholesale pricing, bulk discounts, and worldwide shipping.

📩 Email us now for a fast quote: baiqiying@tianyunc.com

📞 Call us at +8618603715355 for an immediate consultation!