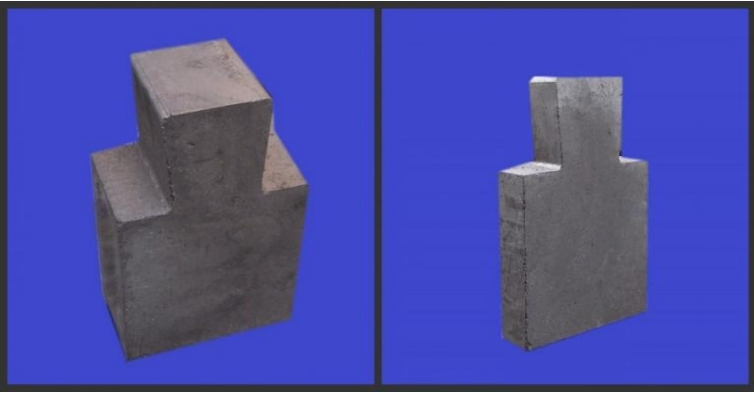

Fired Micro Hole ASC Brick

Raw Material:Dense corundum, supergrade bauxite clinker, high-temperature electric calcined anthracite, graphite, silicon carbide

Advantages:excellent slag resistance and thermal conductivity, protect the cooling wall.

Application:It is used for masonry blast furnace belly, furnace waist and lower furnace lining.

Fired Micro Hole ASC Brick Manufacturer & Supplier

TianYu Refractory Materials Co., LTD is your trusted global manufacturer and supplier of Fired Micro Hole ASC Bricks, engineered for high-temperature industrial applications. With 20+ years of expertise, we provide top-tier refractory solutions that boost efficiency, durability, and cost savings.

⏩ Bulk Orders Available – Contact Us for Best Prices! ⏩

🔥 Why Choose Our Fired Micro Hole ASC Bricks?

✔ Extreme Fire Resistance – Withstands >1750°C, ensuring longevity in steel mills, blast furnaces, and iron ladles.

✔ High Strength & Durability – Cold crushing strength ≥80 MPa, providing maximum load-bearing capacity.

✔ Excellent Thermal Shock Resistance – ≥20 cycles at 1100°C, preventing cracks under rapid temperature changes.

✔ Superior Chemical Stability – Resists molten metal erosion, making it perfect for iron & steel industries.

✔ Precision Engineering – Dimensional accuracy of ±0.5%, ensuring easy installation & long-term reliability.

💡 Your production demands the best – Get a quote today!

🏭 Technical Specifications

| Parameter | Specification |

|---|---|

| Fire Resistance | >1750°C |

| Cold Crushing Strength | ≥80 MPa |

| Apparent Porosity | 16% |

| Bulk Density | 2.6 g/cm³ |

| Thermal Shock Resistance | ≥20 Cycles (1100°C) |

| Chemical Composition (Al₂O₃) | >75% |

| Dimensional Tolerance | ±0.5% |

🔹 Customization Available! Let us know your specific requirements.

CERTIFICATE

TRADE SHOW

🏗️ Applications of Fired Micro Hole ASC Brick

✅ Blast Furnaces – Essential for high-temperature zones requiring extreme heat resistance.

✅ Hot-Blast Stoves – Fired Micro Hole ASC brick ensures long-term reliability under repeated thermal cycles.

✅ Iron Ladles & Torpedo Cars – Protects against molten metal erosion.

✅ Steel Mills & Foundries – Ideal for various high-temperature installations.

💬 Not sure if our bricks fit your needs? Contact our experts now!

🔄 Production Process – Quality You Can Trust

🔸 Raw Material Selection – Premium-grade materials ensure top-notch quality.

🔸 Mixing & Forming – Advanced techniques create uniform and precise brick shapes.

🔸 High-Temperature Firing – Controlled drying & firing enhance durability.

🔸 Rigorous Quality Testing – Ensures strength, porosity & chemical stability.

🔸 Secure Packaging & Global Shipping – Safe, efficient delivery worldwide.

🚀 Bulk orders? Fast production & on-time delivery guaranteed!

🌎 Why Global Buyers Trust TianYu Refractory Materials Co., LTD?

🔹 20+ Years of Expertise – Industry leader in high-performance refractory solutions.

🔹 ISO-Certified Quality – ISO 9001:2015, ISO 14001:2015 & OHSAS 45001:2018.

🔹 Trusted by Steel & Foundry Giants Worldwide.

🔹 Custom Solutions Available – Designed to meet your exact specifications.

📩 Get a quote today – Competitive pricing for bulk orders!

❓ FAQ – Quick Answers for Buyers

🔹 What is the lifespan of Fired Micro Hole ASC Brick?

👉 Depends on application, but designed for long-term use in high-temperature environments.

🔹 Can I order custom sizes?

👉 Yes! We manufacture to your exact specifications.

🔹 How are the bricks packaged for safe shipping?

👉 Wooden pallets with protective wrapping to ensure damage-free delivery.

🔹 What is the lead time for bulk orders?

👉 Typically 2-4 weeks, depending on order quantity.

🔹 Do you provide technical support?

👉 Absolutely! Our experts are available for installation & maintenance guidance.

📞 Contact Us – Let’s Get Started!

💬 Get the best refractory bricks for your business! 📧 Email: baiqiying@tianyunc.com

🌎 Worldwide Shipping – Bulk Discounts Available!

⏩ Act Now – Secure Your Supply of Fired Micro Hole ASC Brick! ⏩