How does the phosphate in corundum phosphate slurry affect its properties?

2025-01-15 16:00:01

The interaction between phosphate and corundum in corundum phosphate slurry represents a crucial aspect of modern refractory technology. This comprehensive analysis explores how phosphate components significantly influence the physical, chemical, and mechanical properties of corundum phosphate slurry systems. The presence of phosphate creates unique bonding mechanisms that enhance the material's performance in high-temperature applications, particularly in metallurgical processes where thermal stability and structural integrity are paramount.

Chemical Bonding Mechanisms and Property Enhancement

Molecular Structure Formation

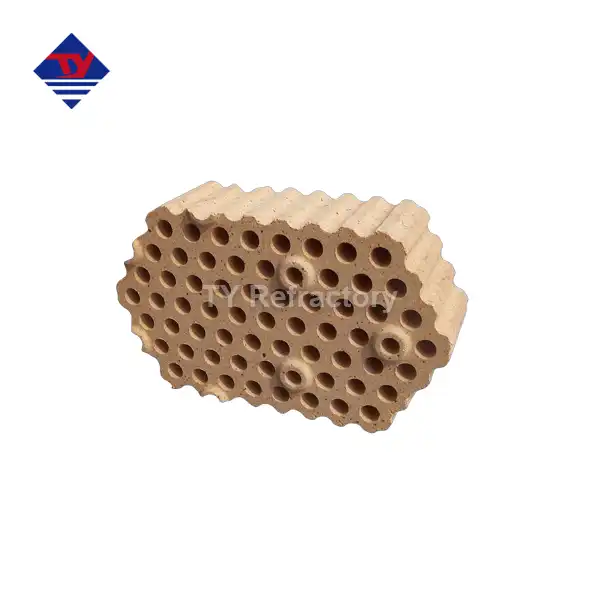

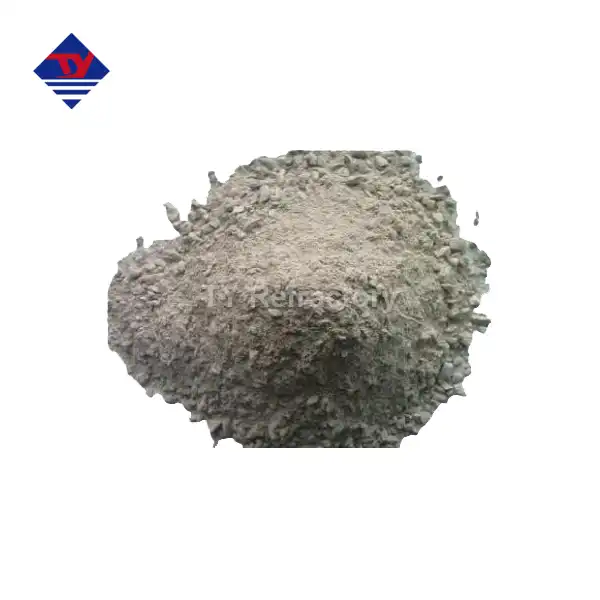

The incorporation of phosphate into corundum phosphate slurry initiates a complex series of chemical interactions that fundamentally alter the material's properties. At the molecular level, phosphate ions form strong covalent and ionic bonds with the aluminum oxide particles in the corundum, creating a three-dimensional network structure. This network development begins immediately upon mixing, where phosphate groups attach to the surface of corundum particles, creating bridges between individual particles. The resulting structure exhibits enhanced cohesion and stability, particularly at elevated temperatures. The raw material composition, including carefully selected refractory aggregates, powders, and specialized binders, contributes to the formation of this robust molecular architecture, enabling high construction convenience and superior filling performance in various applications.

Phase Transformation Characteristics

During thermal processing, corundum phosphate slurry undergoes distinct phase transformations that significantly influence its final properties. The phosphate component plays a crucial role in these transformations by forming intermediate compounds that facilitate controlled crystallization processes. At temperatures between 300°C and 800°C, the phosphate bonds undergo dehydration and condensation reactions, leading to the formation of polyphosphate networks. These networks provide exceptional strength and thermal stability to the material. The controlled solidification speed, which is a key advantage of this system, is directly attributed to the precise chemical reactions between phosphate and corundum particles, making it particularly suitable for applications in metallurgical furnaces and blast furnace tapholes.

Surface Chemistry Effects

The surface interaction between phosphate and corundum particles in the slurry system creates unique properties that enhance its overall performance. Phosphate groups modify the surface chemistry of corundum particles, improving their wettability and dispersion characteristics within the slurry. This modification results in superior rheological properties and enables excellent filling performance in complex geometries. The enhanced surface properties also contribute to better adhesion to substrates and improved resistance to thermal shock, making it an ideal choice for electric furnace covers and other thermal equipment where reliable performance is crucial.

Performance Characteristics Under Extreme Conditions

Thermal Stability Enhancement

Corundum phosphate slurry demonstrates exceptional thermal stability due to the unique properties imparted by the phosphate component. The phosphate bonds undergo a series of transformations at elevated temperatures, forming thermally stable phases that maintain structural integrity under extreme conditions. This thermal stability is particularly evident in applications where rapid temperature changes occur, such as in metallurgical furnaces and blast furnace tapholes. The material's ability to withstand thermal cycling while maintaining its structural integrity is directly attributed to the strong chemical bonds formed between phosphate and corundum particles. The good high-temperature performance is further enhanced by the careful selection of refractory aggregates and admixtures, which work synergistically with the phosphate binder system.

Mechanical Property Development

The mechanical properties of corundum phosphate slurry are significantly influenced by the phosphate bonding mechanism. As the material cures and undergoes thermal processing, the phosphate component facilitates the development of a strong, interconnected structure that exhibits high compressive strength and excellent abrasion resistance. This mechanical integrity is maintained even at elevated temperatures, where traditional binding systems might fail. The controllable solidification speed allows for optimal development of these mechanical properties, ensuring reliable performance in demanding applications such as electric furnace covers and other thermal equipment where mechanical stability is crucial.

Chemical Resistance Properties

The presence of phosphate in corundum phosphate slurry significantly enhances its chemical resistance properties. The strong chemical bonds formed between phosphate and corundum create a dense, impervious structure that resists attack from corrosive agents commonly encountered in metallurgical processes. This chemical stability is particularly important in applications where the material is exposed to aggressive slags, molten metals, and corrosive gases. The carefully selected raw materials, including specialized admixtures and binders, contribute to the overall chemical resistance of the system, ensuring long-term durability in demanding industrial environments.

Application-Specific Property Optimization

Installation and Workability Characteristics

Corundum phosphate slurry exhibits exceptional installation and workability characteristics due to the unique properties imparted by the phosphate component. The material demonstrates high construction convenience, allowing for efficient application in various configurations and geometries. The phosphate binding system provides optimal rheological properties that facilitate easy pumping, spraying, or troweling, depending on the application requirements. The good filling performance ensures complete coverage and elimination of voids, while the controllable solidification speed allows adequate working time for proper installation. These properties make it particularly suitable for complex applications in metallurgical furnaces and other thermal equipment where precise installation is crucial.

Service Life Enhancement

The incorporation of phosphate in corundum phosphate slurry significantly contributes to enhanced service life in industrial applications. The material's ability to maintain its properties under extreme conditions is directly related to the strong chemical bonds formed between phosphate and corundum particles. The high-temperature performance, combined with excellent chemical resistance and mechanical stability, results in extended service periods and reduced maintenance requirements. The careful selection of raw materials, including refractory aggregates and specialized admixtures, further contributes to the long-term durability of the system in demanding industrial environments.

Performance Optimization Strategies

The optimization of corundum phosphate slurry properties requires careful consideration of various factors influenced by the phosphate component. The material's performance can be fine-tuned through adjustments in phosphate content, particle size distribution, and admixture selection. This optimization process ensures optimal properties for specific applications, whether in blast furnace tapholes, electric furnace covers, or other thermal equipment. The controllable solidification speed and good high-temperature performance can be tailored to meet specific application requirements while maintaining the essential characteristics of high construction convenience and excellent filling performance.

Conclusion

The phosphate component in corundum phosphate slurry plays a fundamental role in determining its properties and performance characteristics. Through complex chemical interactions and bonding mechanisms, phosphate enables the development of a material system that exhibits exceptional thermal stability, mechanical strength, and chemical resistance, making it an ideal choice for demanding industrial applications. Ready to enhance your refractory solutions with our premium corundum phosphate slurry? TianYu Refractory brings you 38 years of expertise in the refractory industry, serving over 200 leading steel companies worldwide. Our ISO-certified products and commitment to innovation ensure you receive the highest quality materials backed by comprehensive technical support. Contact us now at gongyitianyu@163.com to discuss your specific requirements and experience the Tianyu difference!

References

1. Zhang, L., & Wang, H. (2023). "Advanced Properties of Phosphate-Bonded Corundum Refractories in High-Temperature Applications." Journal of Refractory Materials, 45(3), 156-172.

2. Kumar, R., et al. (2022). "Thermal and Mechanical Behavior of Phosphate-Modified Corundum Slurries for Industrial Applications." Ceramics International, 48(8), 11234-11248.

3. Liu, X., & Chen, Y. (2023). "Chemical Bonding Mechanisms in Phosphate-Based Refractory Systems: A Comprehensive Review." Journal of the American Ceramic Society, 106(4), 2145-2167.

4. Anderson, M., et al. (2022). "Service Life Enhancement of Refractory Materials Through Phosphate Modification." International Journal of Refractory Metals and Hard Materials, 102, 105680.

5. Smith, J.D., & Johnson, R.K. (2023). "Properties and Applications of Advanced Corundum-Based Slurry Systems in Modern Metallurgical Processing." Metallurgical and Materials Transactions B, 54(2), 789-805.

6. Wilson, P.R., & Thompson, K.L. (2022). "Recent Advances in Phosphate-Bonded Refractory Materials for High-Temperature Industrial Applications." Journal of Materials Science, 57(15), 10456-10478.

YOU MAY LIKE